- Capsule Filling Machine

- Tablet Production Machine

- Powder & Granule Production

- Liquid & Cream Production

- Softgel Production Machine

- Freeze Dryers

- Other

-

LTRJ-50 Lab Type Soft Gelatin Encapsulation Machine

Inquire

-

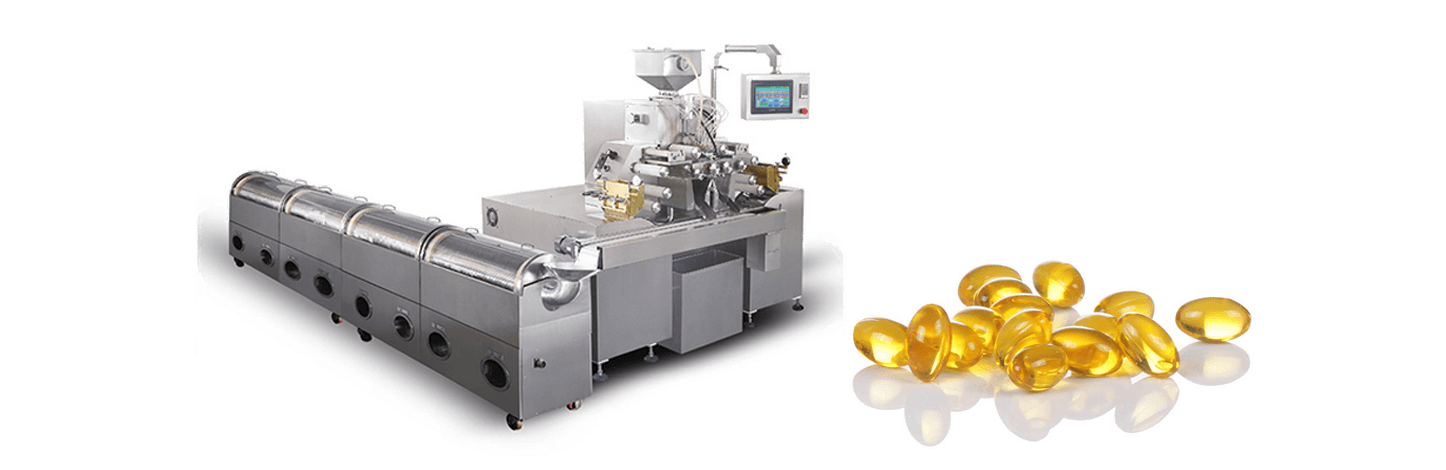

LTRJ Soft Gelatin Encapsulation Machine Soft Gelatin Capsule Making Machine

Inquire

Technical Excellence in Softgel Production

Superior Dosing Accuracy & Yield: Equipped with an advanced linearity driving system, our softgel encapsulation machines ensure a filling precision within $\pm 2\%$. With a capsule package rate of up to 98%, we help manufacturers minimize ingredient waste and maximize production efficiency.

Innovative Wash-Free Technology: Utilizing fine oil supply technology, the gelatin ribbon is lubricated with minimal vegetable oil. This eco-friendly process ensures the finished capsules are "wash-free," significantly reducing post-processing time and operational costs.

Stable & Robust Performance: Featuring high-torque 1.5KW main motors and automatic gelatin level control, our equipment maintains high stability even when processing high-viscosity materials. The integrated automatic supply systems reduce labor intensity while maintaining a clean, professional working environment.

FAQ

-

What types of materials can be processed by a soft gelatin encapsulation machine?

A soft gelatin encapsulation machine is designed to encapsulate a variety of materials, including oils, and liquids such as fish oil, herbal extracts, vitamins, and other pharmaceutical or dietary ingredients.

-

How does a soft gelatin encapsulation machine work?

The machine works by feeding gelatin into a mold from melting tank, where a specific quantity of liquid material is injected into the shell. The filled gelatin capsule is then sealed, forming a soft gel capsule.

-

Are soft gelatin capsules customizable in shape and size?

Yes, soft gelatin capsules can be customized in terms of size, shape, color, and even the type of gelatin used (e.g., plant-based for vegetarian capsules), depending on the needs of the manufacturer.

-

How do you clean and maintain a soft gelatin encapsulation machine?

Cleaning and maintenance involve disassembling parts like the molds and feeding systems, cleaning them thoroughly to prevent contamination, and ensuring that the machine is lubricated and functioning properly. Regular maintenance is important to ensure consistent product quality and machine longevity.

-

What is the production capacity of your softgel machines?

LTPM's range covers everything from the LTRJ-50 lab model, producing 5,000–10,000 pcs per hour, to high-capacity industrial lines like the LTRJ-300. For large-scale manufacturing, our systems can reach an annual output of 300 million granules (based on No.8 oval capsules at 3 RPM), supporting continuous 24/7 operation for 300 days per year.

-

How do you ensure the sealing integrity of the softgel capsules?

By utilizing precision-machined rotary dies and an adjustable injection wedge temperature control system, we guarantee a 100% sealing rate.

-

Does your machine support vegetable/vegan gelatin (starch-based)?

Yes, our latest softgel encapsulation lines are designed to handle both traditional bovine gelatin and plant-based/vegan materials with precise temperature control.

-

What auxiliary equipment is needed for a complete softgel production line?

A complete line typically includes a Gelatin Melting Tank, Service Tank, Tumble Dryer, and Drying Trays. LTPM provides the entire turnkey solution.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China