Why Choose Spray Drying? Key Benefits for Your Process

From Liquid to Powder in Seconds: Achieve instantaneous drying (5-15 seconds) with minimal thermal exposure, perfect for heat-sensitive APIs, probiotics, and food flavors.

Precision Particle Engineering: Control key powder properties—particle size, density, morphology, and moisture content—to optimize flowability, dissolution, and final product performance.

Process Simplification & Scalability: Eliminate multiple batch steps (evaporation, grinding, mixing). Our systems offer seamless scaling from lab trials to continuous production.

GMP-Centric Design: With 316L stainless steel contact parts, clean-in-place (CIP) options, and validation support, our dryers are built for regulated industries.

Ready to Transform Your Liquid Process?

Whether you are developing a new spray-dried API, enhancing a food ingredient, or scaling up a catalyst, the right drying technology is critical. Contact our drying experts today for a consultation.

Product video

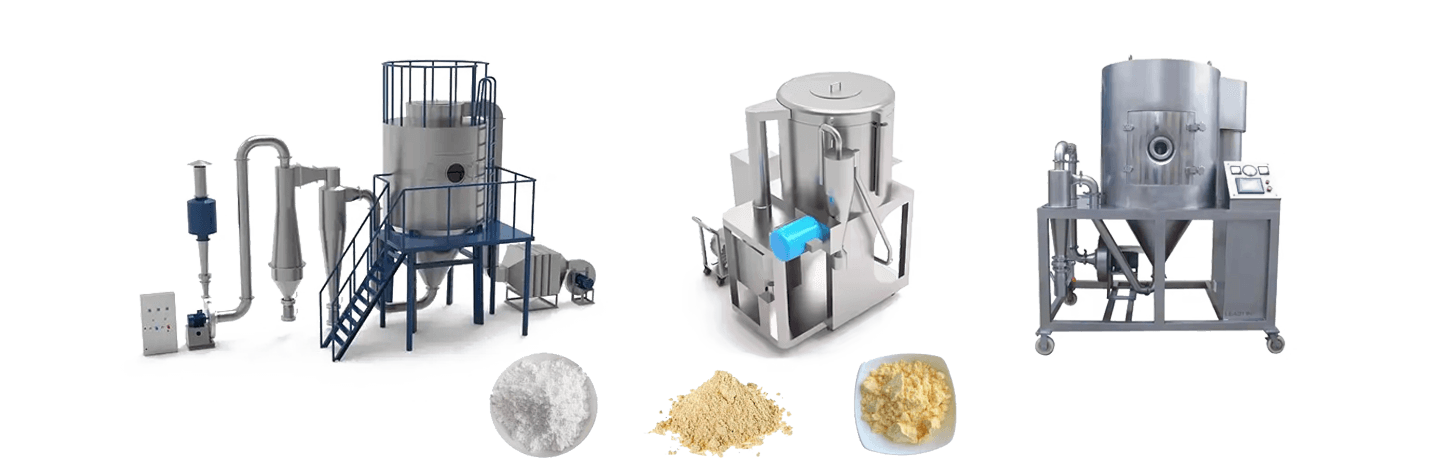

LPG 25 Spray Drying Machine

FAQ

-

What materials are suitable for spray drying?

Ideal for a wide range: Pharmaceutical (antibiotic extracts, vitamin preparations), Food (milk/egg powder, coffee extracts), Chemical (catalysts, ceramics). The key is pumpable liquid form.

-

How is particle size controlled in a spray dryer?

Primarily through atomization. Our LTPG series uses a centrifugal atomizer where wheel speed and feed rate precisely determine droplet size, which directly defines final powder particle size.

-

Can spray drying handle organic solvents?

Yes, with a closed-loop system and inert gas (like N₂) circulation. This is crucial for pharmaceutical processing and flammable solvents. Discuss your solvent with our engineers.

-

How long does it take to turn milk into powder using a centrifugal spray dryer?

The duration depends on the machine model. For example, the LPG-100 model takes approximately 1 hour per batch. Other models may have different processing times based on their capacity and specifications.

-

What are the differences between a pressure spray dryer and a centrifugal spray dryer?

The key differences are based on the type of material and production requirements:

For emulsified and homogenized materials containing oil, a pressure spray dryer is more suitable, as it handles higher production volumes. For example, the smallest HaiJiang machine has a water evaporation capacity of 50kg per hour, but it is more expensive.

For oil-free materials, a centrifugal spray dryer is preferred, especially for lower production volumes. For example, the LPG-5 model has a water evaporation capacity of 5kg per hour and is more affordable. -

What are the heating methods for a pressure spray dryer, and is electric heating suitable for the smallest model?

There are three heating methods: electric heating, thermal oil heating, and steam heating. For the smallest model, electric heating is recommended due to its efficiency and suitability for lower production capacities.

-

How much milk powder can the LPG-5 spray dryer produce in one day if the material is milk?

Given that milk has an 85% water content, the LPG-5 spray dryer can produce approximately 0.9 kg of milk powder per hour. Over a 24-hour period, this translates to around 21.6 kg of milk powder, depending on continuous operation conditions.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China