- Fully Automatic Capsule Filling Machine

- Semi Automatic Capsule Filling Machine

- Liquid Capsule Filling Machine

- Capsule Polishing Machine

-

NJP-Series Fully Automatic High Speed Capsule Filling Machine

Inquire

-

LTFK Series New Generation Fully Automatic Capsule Filling Machine Pharmaceutical Machinery

Inquire

-

CapTop Series New Design Fully Automatic High Speed Capsule Filling Machine

Inquire

LTPM's fully automatic capsule filling machines are designed for high-speed, accurate, and hassle-free capsule production. Equipped with advanced programmable control systems and touchscreen panels, these machines are easy to operate and adjust. They automatically complete every step—capsule positioning, separation, filling, and locking—ensuring smooth and efficient operation.

Features of Our Automatic Capsule Fillers

Wide Application & Flexibility

These machines work with a variety of materials, including powders, pellets, granules, herbal medicines, and nutritional supplements like vitamins. They support capsule sizes from 00# to 5#, making them suitable for different production needs.

High Speed & Adjustable Capacity

With speeds ranging from 200 to 5,500 capsules per minute, our machines meet both small-scale and large-scale production demands. The compaction filling system allows individual adjustment at each station, ensuring precise control over capsule weight. The gap between the dosing disc and compaction plate is adjustable, minimizing powder waste.

Smart & Reliable Operation

Built-in sensors monitor the product hopper and empty capsule hopper, preventing interruptions and ensuring optimal filling. The electronic auto-counter and variable speed control enhance efficiency and accuracy.

Ideal for pharmaceutical and nutraceutical industries, our fully automatic capsule fillers deliver high performance, consistency, and minimal maintenance. As a trusted supplier of capsule filling machines, we provide reliable and user-friendly solutions to optimize your production line. Contact us and Upgrade with our advanced machines today!

Product video

Powder & Granule Production

Captop capsule filling

Solid Dosage Solutions

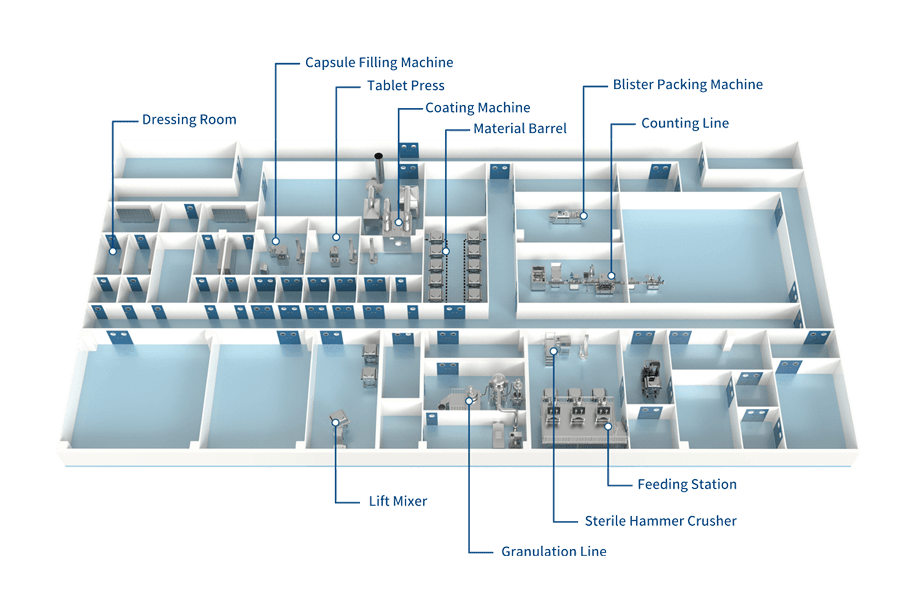

LTPM portfolio includes powder handling, granulating, drying, capsule filling, tablet compression, and coating equipment for both batch and continuous manufacturing applications, as well as a variety of solutions for contained processing for oral solid dosage (OSD) form.

Learn More

Latest news

Learn MoreFAQ

-

The vacuum pump of the double-head semi-automatic capsule filling machine leaks oil and heats up. Why?

There are three reasons: The cloth bag is blocked, the voltage is unstable, and the seal is not good.

-

Does the capsule filling machine need a water chiller?

If it is a water ring vacuum pump, water is required for sealing to generate vacuum condition. But we will distribute the water tank to protect the vacuum pump from damage caused by overheating. Of course, if you are going to use dry vacuum pump, it won’t need any water or oil for Automatic capsule filling machine.

-

What kinds of material transfers are available for the automatic capsule filling machine?

The automatic capsule filling machine has an empty capsule feeder and a powder feeder.

-

How much does a fully automatic capsule filling machine cost?

The price of fully automatic fillers range from $15000 - $150000. Final pricing depends on capacity, automation level, and added functionalities like PAT monitoring or containment systems.

2025.04.28

2025.04.28

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China