Capsule filling machines are the backbone of pharmaceutical and nutraceutical production, ensuring precise dosing and efficient encapsulation. From life-saving medications to daily supplements, these machines automate what would otherwise be a slow, error-prone manual process.

Whether you're a manufacturer, researcher, or simply curious, understanding their operation is key. This guide breaks down the mechanics, types, and applications of capsule fillers. Let’s dive in.

A capsule filling machine is pharmaceutical equipment for precisely filling empty capsules with powders, granules or pellets. These machines are categorized by scale: industrial automatic fillers for mass production, and manual / semi-automatic capsule fillers for small-batch or personal use. Widely used in pharma, nutraceutical and supplement industries, they ensure dosing accuracy and production efficiency. Learn more about capsule filling machine types.

Automatic Capsule Filling Machine Video

Among the various types of capsule filling equipment, fully automatic machines represent the most sophisticated and technologically advanced systems. Their complex architecture integrates multiple precision subsystems to achieve high-speed, GMP-compliant production. Here we examine the working principle using a fully automatic capsule filler as the primary example:

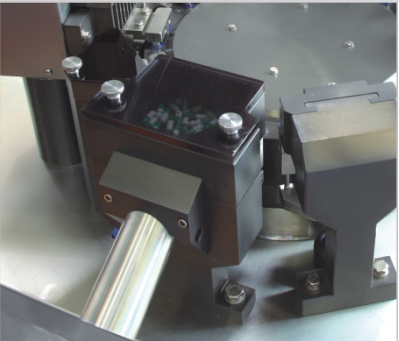

Upon entering the machine, capsules initially land in random orientations - either body-down or cap-down. The horizontal and vertical forks actively push and adjust each capsule's position through physical contact. This mechanical interaction ensures all capsules bend downward when entering the segment, achieving perfect body-down alignment.

The pre-oriented capsules are precision-loaded into the perforated tray in body-down position. The tray's capacity is determined by its precision-drilled holes, each sized to hold one capsule.

After the capsule tray transfers the capsules to the separation station, the vacuum system then splits caps from bodies. Finally, the separated components move to their dedicated processing tracks.

After capsule separation, a small number of empty capsules fail to separate for various reasons. The machine uses ejector pins positioned near the capsules. If the capsule caps are still attached to the bodies after the separation process, these pins pull the unseparated capsules out of the mold. Then, the rejected capsules are blown into waste collection bags. Only the properly separated capsule bodies and caps proceed to the next stations for further processing, such as filling and locking.

Capsule Filling Once separated, the capsule bodies move to the filling station. This critical stage primarily employs two filling methods:

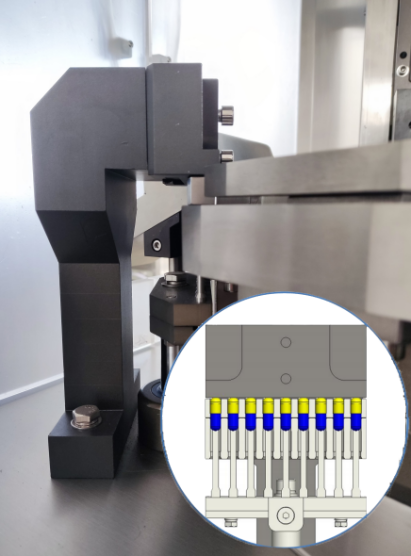

Tamping pin capsule filling

The most common method uses a rotating dosing disc with multiple holes. Powder fills the holes where tamping pins compress it through 5-6 successive compactions. The disc then rotates to deposit the compacted powder into capsules. This method offers high speed and ±3% dosing accuracy.

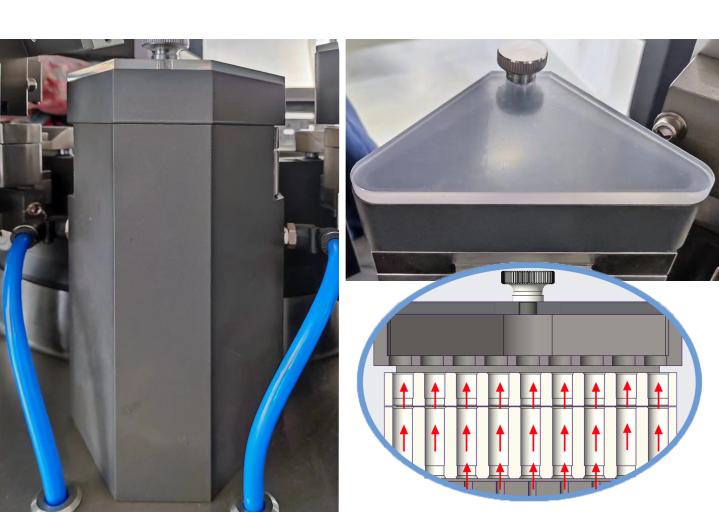

Dosator capsule filling

The dosator system uses a simple piston mechanism to fill capsules. First, the dosator tube presses into the powder bed, allowing material to enter its cavity. Then, an internal pin compresses the powder into a solid slug. Finally, the piston pushes this precise dose directly into the capsule body.

While slower than tamping methods, this single-piston design excels at micro-dosing. It can accurately fill tiny amounts of powder (1-50mg), making it ideal for potent drugs where precision matters most.

At the locking station, aligned upper and lower trays position capsule bodies and caps for closure. A precision mechanism with a pin plate and baffle plate applies controlled force to securely lock the components, ensuring proper encapsulation before ejection.

The machine uses the same component for ejection as for rejection. A pin pushes the locked capsules out into the capsule tray, then compressed air blows the ejected locked capsules into the capsule outlet.

After completing the filling cycle, the capsule tray returns to the rectification station. Any remaining defective capsules or residual powder in the tray must be cleared before restarting operations. Directed compressed air thoroughly cleans the tray by blowing all contaminants into the integrated dust collection unit at the base.

Capsule filling machines serve critical roles across multiple industries requiring precise dosage forms:

Pharmaceutical Manufacturing: These machines produce solid oral dosage forms for antibiotics, probiotics, and OTC medications. They handle both immediate-release formulations and modified-release products requiring specialized capsule types.

Nutraceutical Production: Operators use them to encapsulate herbal extracts (like ginseng or turmeric), vitamins (particularly B-complex and D3), and sports nutrition powders (protein blends, pre-workout formulas).

Cosmetic capsules for oral beauty supplements (collagen, hyaluronic acid)

Clinical trial materials requiring precise low-dose formulations

Capsule filling machines play a vital role in pharmaceutical, nutraceutical, and specialty product manufacturing by ensuring precise dosing and efficient encapsulation. Understanding their working principles and key performance factors helps operators maximize production quality and output.

As a leading capsule filling machine manufacturer, LTPM provides reliable automatic and semi-automatic capsule fillers tailored to diverse production needs. contact us by [email protected] today for high-speed, precision filling machines!

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.