In both the food and pharmaceutical industries, preserving the integrity of sensitive materials is crucial. Two widely used methods for removing moisture are freeze drying and dehydration. While they share a similar goal—extending shelf life by reducing water content—they differ significantly in process, results, and application.

Understanding these differences is key to selecting the right technology for your specific needs. In this article, we explore how freeze dryers and dehydrators work, compare their advantages and limitations, and help you determine which method is better suited for various use cases—from long-term food storage to pharmaceutical processing. Let’s dive into the details.

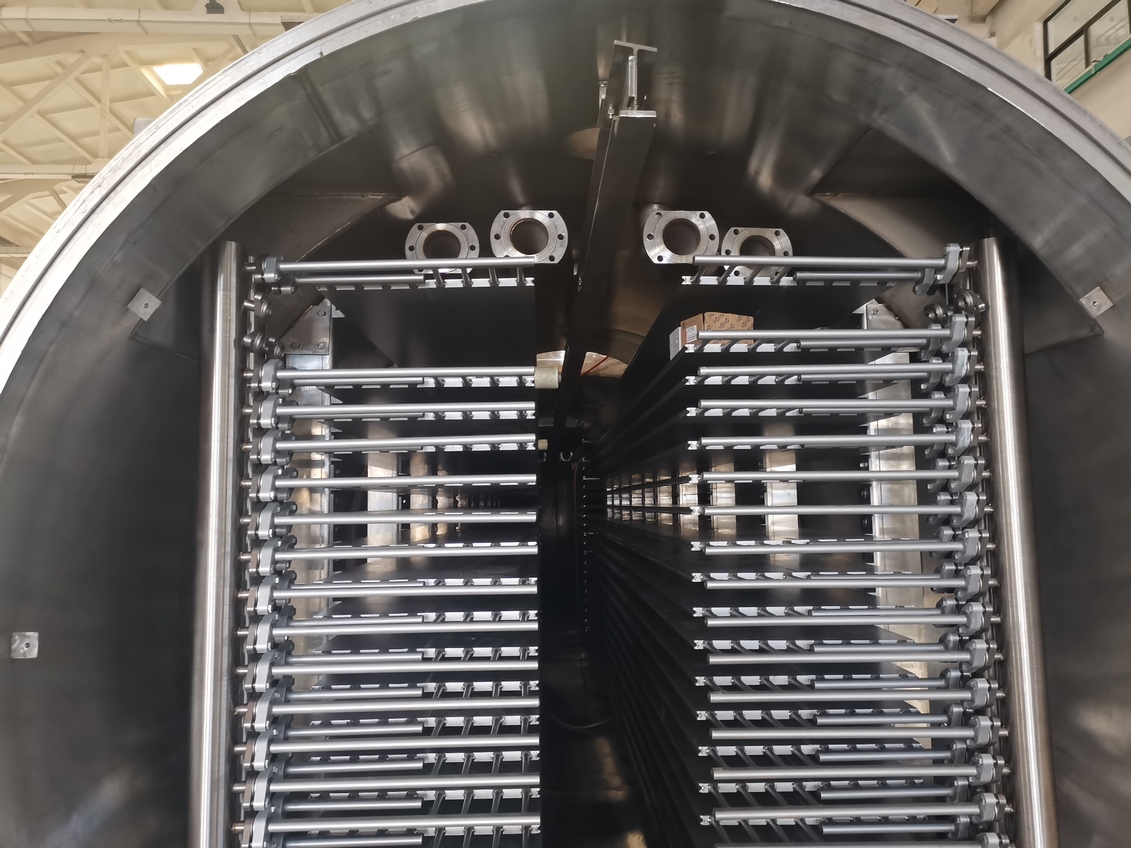

A freeze dryer, also known as a lyophilizer, is a specialized device used to remove water from a product after it has been frozen. The process, called freeze-drying or lyophilization, involves three main stages: freezing, primary drying (sublimation), and secondary drying (desorption).

First, the material—such as a pharmaceutical solution or food product—is frozen at very low temperatures. Then, under a deep vacuum, the ice is turned directly into vapor through sublimation. This avoids the damaging effects of liquid water and high heat. Finally, in the secondary drying phase, any remaining bound water is removed by raising the temperature slightly.

This gentle and precise method helps preserve the original structure, potency, and quality of sensitive materials, making freeze dryers especially valuable in the pharmaceutical and biotech industries.

A dehydrator is a device that removes moisture from pharmaceutical intermediates or excipients using controlled heat and airflow. Unlike lyophilization, this process relies on evaporation, where water is turned into vapor through exposure to elevated—but not extreme—temperatures.

The material is placed inside the dehydrator, where warm air circulates evenly. Over several hours, the heat gradually draws moisture out, leaving behind a dried product with reduced water content. This helps prevent microbial growth and spoilage while extending shelf life.

Dehydration is a cost-effective and energy-efficient method, commonly used for drying herbal extracts, non-sensitive excipients, or pre-formulation ingredients. However, due to the use of heat, it may not be suitable for thermally unstable drugs or final dosage forms requiring high structural or functional integrity.

When comparing lyophilization and dehydration for pharmaceutical use, it's important to understand how they differ across key technical and operational aspects. While both methods aim to reduce moisture content for better stability and longer shelf life, their approaches — from process mechanics to system requirements — are fundamentally different and influence the final product in distinct ways.

Below is a detailed comparison between lyophilizers (freeze dryers) and dehydrators, tailored specifically for pharmaceutical applications:

| Feature | Lyophilizer | Dehydrator |

|---|---|---|

| Working Principle | Based on sublimation — ice is directly converted into vapor under vacuum without passing through the liquid phase. | Based on evaporation — heat and airflow are used to vaporize water from the material. |

| Temperature Environment | The process starts with freezing at -40°C to -50°C, followed by primary drying under vacuum at -20°C to 10°C, making it ideal for heat-sensitive drugs such as proteins, vaccines, and biologics. | Requires heating at 50°C to 90°C, which may affect the activity of thermally unstable components. |

| Preservation of Product Properties | Maintains the original structure, activity, and solubility of the product. Suitable for high-value injectables and sterile formulations. | May cause partial loss of activity or structural changes, better suited for non-sensitive excipients or intermediates. |

| Process Control Precision | Highly controllable with programmable parameters (temperature, pressure, time), meeting GMP requirements. | Simpler control system, less suitable for critical pharmaceutical drying processes. |

| Drying Time | Longer processing time, typically 24–72 hours per batch depending on formulation complexity. | Faster drying cycle, often completed within several hours. |

| Energy Consumption & Cost | Higher energy consumption due to vacuum and refrigeration systems; higher initial and operational costs. Commercial Price: $15,000 – $50,000+. | Lower energy consumption and more cost-effective for basic drying needs. Commercial Price: $1,000 – $3,000. |

| Cleanliness & Sterilization | Often equipped with SIP (Sterilization-in-Place) and CIP (Cleaning-in-Place) functions; suitable for sterile drug manufacturing. | Limited cleaning and sterilization capabilities; less common in final sterile dosage production. |

| Typical Applications | Used for freeze-dried injectables, biopharmaceuticals, diagnostic reagents, and lyophilized probiotics. | Commonly used for drying herbal extracts, pre-mixes, and non-sensitive excipients like lactose or starch. |

In pharmaceutical manufacturing, lyophilizers are the preferred choice for handling thermally sensitive, high-value products, especially those requiring long-term stability and structural integrity. Dehydrators, while more economical and faster, are generally used in earlier stages of production — such as drying raw materials or excipients — where thermal sensitivity and precision are less critical.

This distinction defines their roles in the pharmaceutical production line: lyophilization is part of the finishing process that determines final product quality, while dehydration serves more as a preparatory step for upstream materials.

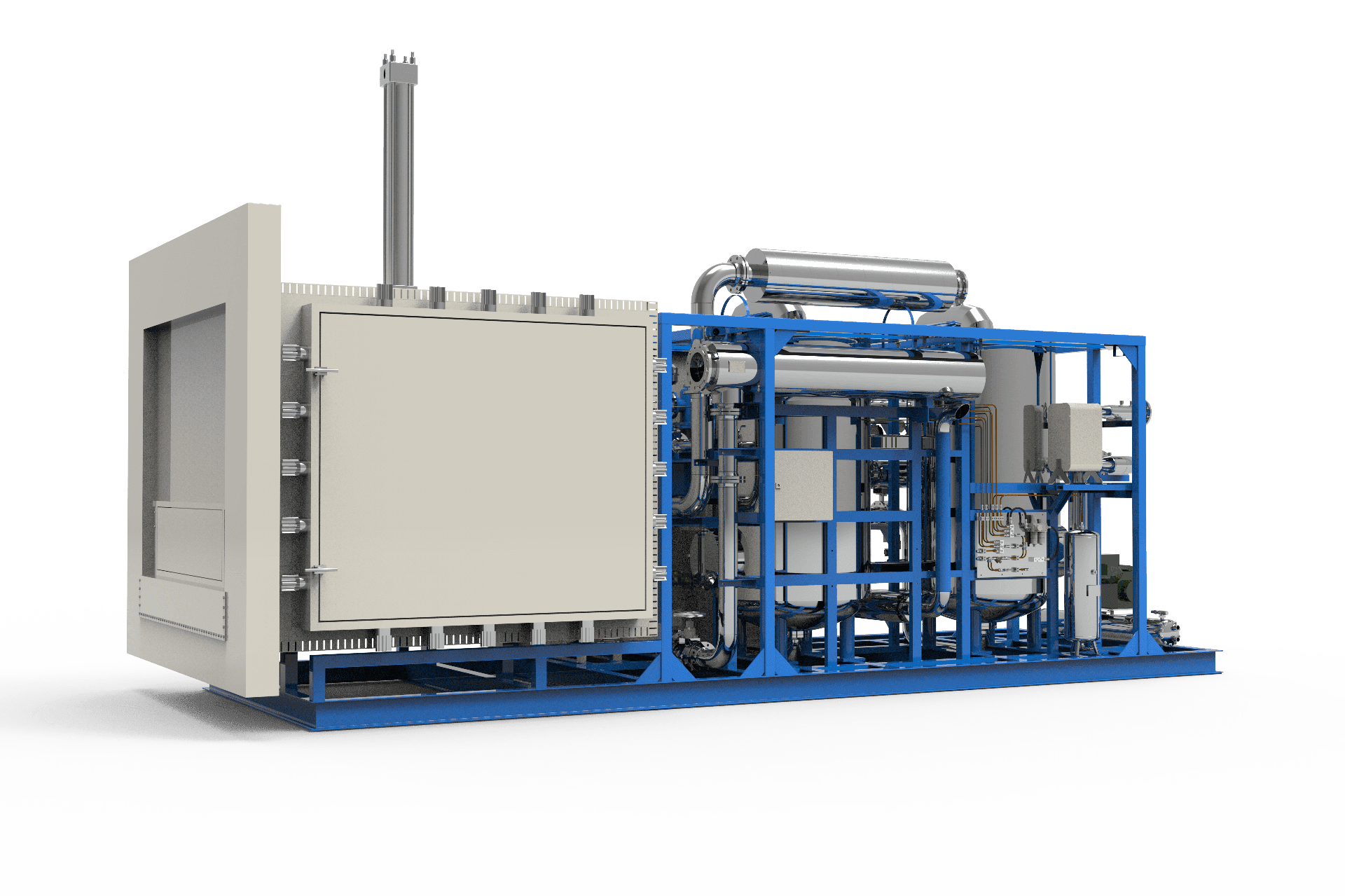

Industrial Freeze Dry Machine

A freeze dryer is a device that uses freeze-drying technology—also known as sublimation drying—to remove moisture from materials. This method preserves the structure, composition, and activity of the original substance, making it highly valuable across various industries.

Food industry: freeze dryers are widely used to produce high-quality dried food products such as fruits, vegetables, instant meals, and pet food. Freeze-dried foods retain most of their nutrients, flavor, color, and texture, making them ideal for long-term food storage, outdoor adventures, emergency preparedness, and even space missions.

Pharmaceutical industry: freeze drying is a critical process for preserving heat-sensitive drugs, including vaccines, antibiotics, proteins, and biologics. By removing water at low temperatures, the bioactivity of these medications is maintained, ensuring stability and extending shelf life.

Scientific research and biotechnology: preserving biological samples such as tissue, bacteria, enzymes, and DNA. In the cosmetic industry, they help maintain the potency of natural extracts and active ingredients in skincare products.

Food industry: dehydrators are extensively used to create dried fruits, vegetables, herbs, and meats (such as jerky). These products are favored for their convenience, portability, and long-term storage capabilities without the need for refrigeration. Home cooks and professionals alike use dehydrators to preserve seasonal produce, make healthy snacks, and prepare ingredients for culinary uses like seasoning blends or garnishes.

Agricultural: Dehydrators are used to dry grains, seeds, and crops post-harvest, ensuring these products remain stable and free from mold during storage. In some cases, dehydrators are employed to reduce the weight and volume of agricultural products for easier transportation and distribution.

Pharmaceutical and herbal medicine industries: dehydrators are utilized to dry medicinal plants and herbs, preserving their active compounds and enabling their use in teas, tinctures, and supplements. The gentle drying process helps maintain the integrity of the plant's therapeutic properties.

Superior Nutrient Retention: Preserves up to 95–97% of nutrients, vitamins, and enzymes due to low-temperature processing.

Long Shelf Life: Freeze-dried foods can last 15–25 years when properly sealed, making them ideal for emergency preparedness and long-term storage.

Excellent Flavor and Texture Retention: Foods maintain their original taste, color, and texture. They rehydrate quickly and closely resemble fresh food.

Versatile: Can be used for a wide range of foods including fruits, vegetables, meats, dairy, full meals, and even coffee.

Lightweight: Ideal for backpacking, camping, and military rations due to low weight after drying

High Cost: Freeze dryers are expensive, with home units starting around $15,000 – $50,000.

Large Footprint: They are bulky and require significant space.

Long Processing Time: A single batch can take 20–40 hours.

High Energy Consumption: Uses more electricity than dehydrators due to vacuum and freezing processes.

Not Ideal for Small-Scale Use: Better suited for large batches and long-term use rather than occasional drying.

Affordable: Dehydrators are much cheaper, ranging from $1,000 – $3,000 depending on size and features.

Compact and Portable: Easy to store and use in small kitchens.

Simple to Use: Requires minimal setup and monitoring.

Quick Drying Time: Most batches complete in 6–24 hours, depending on the food.

Energy Efficient: Uses less electricity compared to freeze dryers.

Great for Snacks: Ideal for making fruit leather, jerky, dried herbs, and vegetable chips.

Lower Nutrient Retention: Heat can degrade some vitamins and enzymes, especially heat-sensitive ones like vitamin C.

Shorter Shelf Life: Dehydrated foods typically last 6 months to 5 years, depending on storage conditions.

Altered Texture and Flavor: Food becomes chewy or leathery, and some flavor may be lost during drying.

Limited Rehydration: Not ideal for full meals or dishes that require rehydration to original form.

Not Suitable for All Foods: Dairy, eggs, and high-fat foods don’t dehydrate well and can spoil.

In conclusion, both freeze dryers and dehydrators offer valuable solutions for preserving materials, but they serve very different needs — especially across industries. For the pharmaceutical sector, where maintaining the bioactivity, stability, and long-term integrity of sensitive compounds is critical, freeze drying (lyophilization) is the gold standard. Unlike dehydration, freeze drying operates at low temperatures, minimizing degradation and ensuring that vital proteins, vaccines, and injectables remain effective over extended periods.

At LTPM, we are a trusted manufacturer of professional pharmaceutical machinery, offering a comprehensive range of equipment including capsule filling machines, tablet press machines, and industrial freeze dryers. Our freeze drying systems are designed to meet the strict requirements of pharmaceutical production, ensuring consistent performance, GMP compliance, and efficient large-scale processing.

Contact us today by [email protected] to learn more about our freeze dryers and other pharmaceutical equipment, or to request a customized solution for your production process.

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.