Tablet coating machines play a vital role in pharmaceutical manufacturing by applying a thin, uniform layer to tablets. This process enhances drug stability, controls release rates, and improves patient acceptability. Understanding the working principle of these machines is key to optimizing coating quality and efficiency. This article explains how tablet coating machines operate, their critical components, and the science behind effective coating.

Tablet coating machine is a key equipment in the pharmaceutical and food industries. It is a complex system composed of multiple indispensable components. These components work together to ensure precise and efficient coating. Before understanding its principle, let's take a look at its main components.

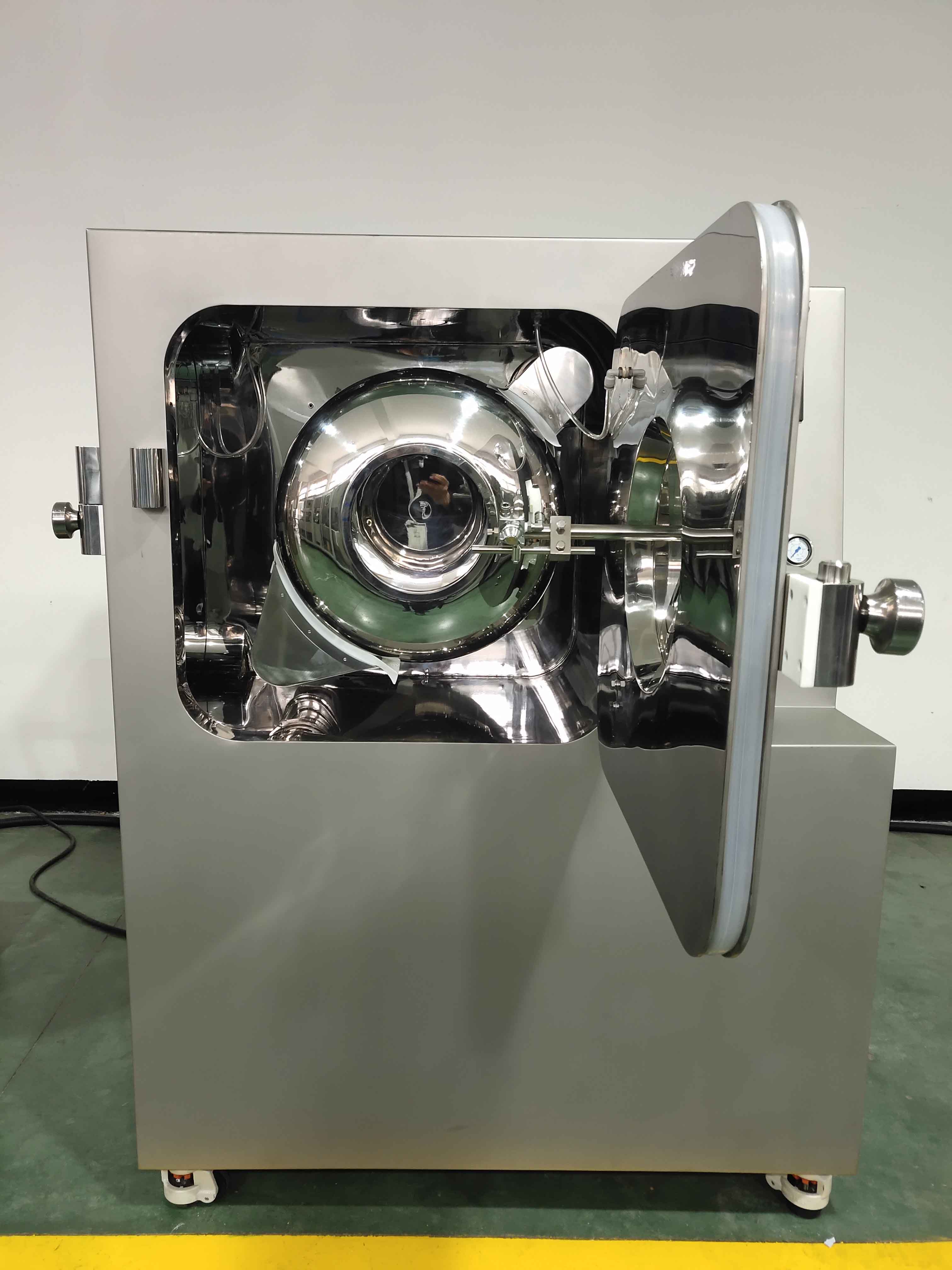

The coating pan or drum is the core component of a tablet coating machine where tablets are loaded for the coating process. It serves as the chamber that holds the tablets during operation and is designed to rotate smoothly. Common types include perforated drums and non-perforated drums, depending on air distribution methods.

The spray system atomizes the coating solution into a fine mist and applies it evenly onto tablets. It consists of spray nozzles, which are positioned above the drum for uniform coverage, and a peristaltic pump that precisely controls the solution flow rate. This system ensures consistent coating quality and accurate application.

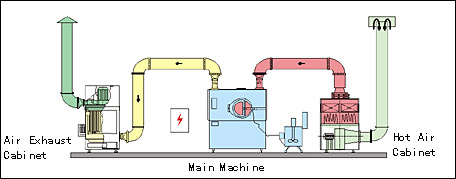

The airflow and drying system supplies and controls heated air for coating drying. It includes an air inlet fan, heating unit, and filters. Key adjustable parameters are temperature, air volume, and drum pressure. This system ensures efficient and uniform drying of the coating layer.

The exhaust system removes moisture, solvent vapors, and particles from the coating chamber. It includes outlet ducts and filters or scrubbers to meet GMP and environmental standards. This system helps maintain a clean, safe environment and prevents contamination during the coating process.

The working principle of a tablet coating machine is based on the continuous movement of tablets within a rotating drum, combined with precise spraying and controlled drying. Tablets are loaded into the coating pan or drum, which rotates to create an even tumbling motion. As the tablets move, a spray system applies a fine mist of coating solution onto their surfaces.

Simultaneously, a controlled airflow system introduces heated air into the chamber, rapidly drying the coating after each application. This ensures that each layer sets properly before the next is applied. The process may be repeated in multiple cycles to achieve the desired coating thickness and performance characteristics.

Modern coating machines use programmable logic controllers (PLC) and human-machine interfaces (HMI) to maintain consistent parameters such as drum speed, temperature, spray rate, and air pressure. This automation ensures high-quality, repeatable results while meeting GMP standards.

Before starting the coating operation, both the tablet batch and the coating solution must be carefully prepared. The solution may consist of water-soluble polymers, sugar-based mixtures, or organic solvents, depending on the desired release profile—such as immediate, sustained, or enteric release.

Once the materials are ready, tablets are loaded into the rotating drum (or coating pan) of the machine. Proper loading is critical—overfilling can lead to uneven coverage and mechanical damage, while underfilling may reduce efficiency and increase processing time. Most modern machines include fill-level indicators or automated sensors to ensure optimal loading.

Before any coating is applied, the tablets undergo a preheating or thermal conditioning phase. This step removes surface moisture and prepares the tablet core for better adhesion of the coating layer.

It also helps maintain thermal equilibrium during the subsequent drying cycles, ensuring consistent evaporation of solvents once spraying begins.

With the tablets conditioned, the spray system activates. The coating solution is atomized into a fine mist using high-precision nozzles positioned above the tablet bed. As the drum rotates, tablets tumble through the spray zone, ensuring full and even coverage.

The peristaltic pump precisely controls the flow rate of the solution, while the spray pattern and pressure are adjusted based on tablet size and shape.

Simultaneously with spraying, a controlled airflow system introduces heated air into the chamber. This airflow evaporates the solvent from the freshly applied coating, allowing it to solidify quickly and adhere firmly to the tablet surface. Proper temperature and humidity control are essential to prevent defects such as cracking, peeling, or sticking between tablets.

Depending on the required thickness and functionality of the coating, the spraying and drying steps are repeated multiple times. Each cycle applies a thin, uniform layer to gradually build up the final coating.

This multi-layer approach is especially important for functional coatings such as:

Enteric coatings, which resist stomach acid

Sustained-release coatings, which control drug absorption over time

Sugar coatings, which enhance appearance and taste masking

Each repeat cycle follows the same principles but may involve adjustments in spray rate, temperature, or dwell time.

After the final coating layer has dried, the tablets enter a cooling phase. This step allows the coating to fully harden and stabilizes the product before discharge.

Cooling typically involves reducing the inlet air temperature while maintaining gentle airflow. It’s crucial to avoid abrupt temperature changes that could cause stress cracks or delamination of the coating.

Once cooled, the tablets are discharged from the coating machine and transferred to downstream processes such as inspection, sorting, or packaging.

Careful handling during discharge is essential to preserve the integrity of the delicate outer layer. Some machines feature automatic unloading systems with vibration control to minimize impact and abrasion.

| Parameter | Typical Range | Description |

|---|---|---|

| Drum Speed (RPM) | 10 - 30 RPM | Rotation speed affects tablet tumbling and coating uniformity. |

| Inlet Air Temp (°C) | 40 - 80°C | Higher temps accelerate drying but risk thermal damage. |

| Outlet Air Temp (°C) | 35 - 60°C | Monitors drying efficiency; should not exceed tablet tolerance. |

| Air Volume (m³/min) | 200 - 1000 m³/min | Affects drying rate and uniformity of coating. |

| Spray Rate (ml/min) | 50 - 500 ml/min | Controlled by pump; affects coating thickness and coverage. |

| Spray Pressure (bar) | 1 - 3 bar | Determines mist fineness; higher pressure may cause overspray. |

| Batch Size (kg) | 5 - 600 kg | Depends on machine capacity and production scale. |

| Solution Viscosity (cP) | 10 - 100 cP | Impacts atomization quality and coating thickness. |

| Drying Time (min) | 5 - 30 minutes | Varies with coating type, temp, and airflow settings. |

| Cooling Time (min) | 5 - 15 minutes | Ensures stability of the coating before discharge. |

These parameters should be closely monitored and optimized for each specific coating application to ensure consistent quality and compliance with regulatory standards.

The tablet coating process is a complex yet highly controllable procedure that plays a vital role in pharmaceutical production. From preparation to discharge, each stage contributes to the final product's performance, appearance, and safety.

Understanding the function of each machine component, the sequential steps of the coating process, and the influence of technical parameters enables manufacturers to achieve high-quality results efficiently and reliably.

Whether you're producing sugar-coated tablets or developing advanced sustained-release formulations, our coating systems are engineered to deliver consistent performance across diverse applications.

Reach out to us by [email protected] to discover how we can help optimize your production line.

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.