Have you ever wondered how your daily vitamins, painkillers, or even CBD tablets are made? The answer lies in a small but powerful machine known as a pill press. Whether you're involved in the pharmaceutical industry, work with dietary supplements, or are simply curious about how medications are manufactured, understanding what a pill press is can open up a whole new perspective on modern medicine production.

In this comprehensive guide, we’ll walk you through everything you need to know about what a pill press is, how it works, its different types, applications, and even legal considerations surrounding its use. By the end of this article, you’ll have a clear understanding of why pill presses are essential tools in both large-scale manufacturing and small-scale research settings.

A pill press, also known as a tablet press, tablet compression machine, or pill-making machine, is a mechanical device used to compress powdered substances into solid tablets of uniform size and weight. This process is widely used in the pharmaceutical industry to produce pills containing active medicinal ingredients.

The primary purpose of a pill press is to ensure that each tablet contains an exact dosage of the intended substance, whether it’s a life-saving drug, a vitamin supplement, or a herbal compound. These machines come in various sizes and complexities, from small benchtop models used in laboratories to large industrial rotary presses capable of producing thousands of tablets per minute.

Beyond the pharmaceutical industry, pill presses are widely used in the production of nutraceuticals, veterinary medications, and industrial compounds, supporting efficient and standardized tablet manufacturing at scale.

Pill presses are more than just machines; they are critical tools that ensure the safety, efficacy, and affordability of pharmaceutical products. Here’s why they are indispensable to modern healthcare.

Each tablet must contain the precise amount of active ingredient to be both effective and safe. Pill presses guarantee this consistency, minimizing the risks of underdosing or overdosing and ensuring patient safety.

Manual production of millions of tablets would be impractical and prohibitively expensive. Automated pill presses allow for rapid, cost-effective manufacturing, meeting global healthcare demands with precision and reliability.

During clinical trials, researchers rely on pill presses to manufacture trial medications under controlled conditions. This ensures accurate data collection and compliance with regulatory standards, accelerating the development of new treatments.

By optimizing production speeds and minimizing material waste, pill presses help lower overall manufacturing costs. These savings can be passed on to consumers, making essential medications more affordable and accessible.

With their ability to enhance efficiency, reduce costs, and ensure consistent quality, pill presses are a cornerstone of modern pharmaceutical manufacturing. Whether you're producing life-saving medications or innovative supplements, investing in reliable pill press technology is key to success.

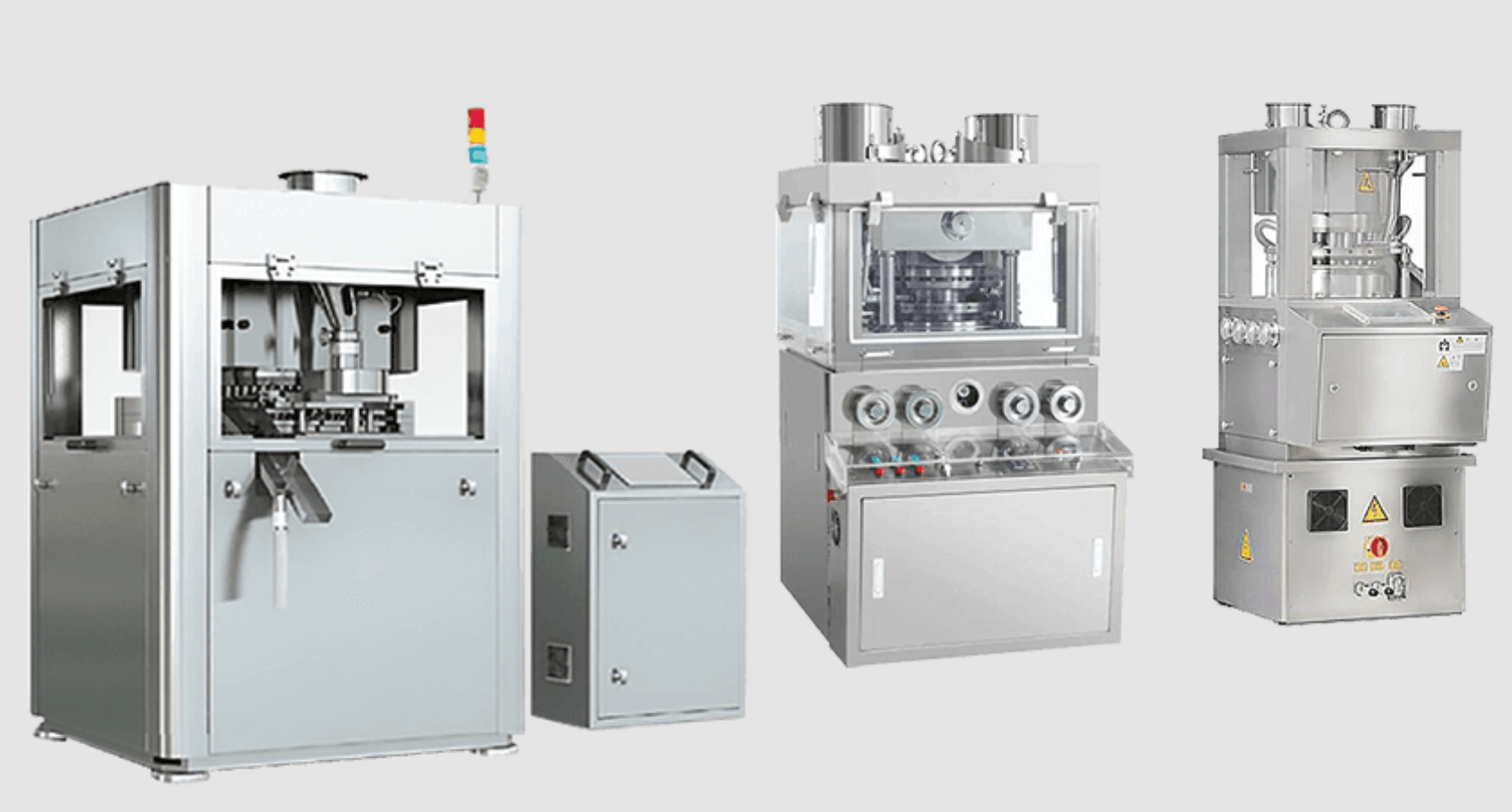

Pill presses come in several varieties, each suited to specific applications and production scales. Understanding the different types of pill presses is paramount in selecting the right machine for your manufacturing needs. Below is a detailed breakdown of the most common types:

Also known as a single-station press, this is the simplest type of pill press, using one set of punches and a single die to compress powder into tablets. Ideal for small-scale production, labs, and educational purposes.

Pros:

Affordable

Easy to operate and maintain

Portable

Cons:

Low output (usually under 50 tablets/minute)

Not suitable for high-volume production

Our ZTP-60 Single Punch Tablet Press is a robust and precision-engineered machine designed for industrial applications. While single-station presses are typically used for small-scale production, the ZTP-60 offers enhanced performance with a working pressure of 60T and a capacity of up to 1,200 tablets per hour. It is ideal for pressing disinfectants, salt blocks, sanitary products, chemical powders, and more. Built to handle corrosive materials, this press ensures durability, uniform tablet quality, and reliable continuous operation.

Rotary tablet presses are designed for large-scale pharmaceutical manufacturing, featuring multiple stations rotating around a central turret. These machines can produce hundreds to thousands of tablets per minute with exceptional consistency in weight, hardness, and shape.

Pros:

High efficiency and speed

Uniform tablet quality

Suitable for continuous production

Cons:

Expensive

Complex setup and maintenance

Our ZP Series Rotary Tablet Press is a high-performance automatic press designed for continuous tablet production. Ideal for pharmaceutical, chemical, and food industries, it offers precise compression of granular materials into uniform tablets. With models ranging from 9 to 31 stations, it delivers high output—up to 55,000 tablets per hour—making it perfect for large-scale manufacturing.

An automatic tablet press integrates advanced automation into the process, making it ideal for industrial production lines. These machines come with sophisticated control systems for real-time monitoring and adjustment of production parameters, ensuring consistent tablet quality while minimizing human intervention.

Features

Online monitoring and adjustment capabilities

Integrated features like tablet dedusters or metal detectors for improved product quality and safety

Ideal For: Large pharmaceutical manufacturing plants where precision and high output are crucial.

All our pill press machines are fully automatic, designed to streamline production with advanced control systems. Suitable for pharmaceutical, chemical, and food industries, they ensure precise tablet compression, high output, and minimal downtime.

A multi-station tablet press is a specialized type of rotary press capable of producing tablets in different sizes or shapes simultaneously. This flexibility makes it an excellent choice for companies that need to switch between different product lines easily.

Advantages

Highly customizable with different punch and die sets

Widely applied in pharmaceutical and nutraceutical industries demanding diverse tablet formulations

Our GZP Series High-Speed Rotary Tablet Press is a multi-station solution designed for large-scale, high-precision production. Capable of pressing round, oval, and irregular tablets with excellent consistency, it meets GMP standards and supports pharmaceutical, food, and chemical applications. With output reaching hundreds of thousands per hour, it ensures efficiency, accuracy, and reliability in demanding industrial environments.

Hydraulic presses apply pressure through liquid to compress powder into tablets, suitable for materials requiring larger compaction forces than those provided by mechanical presses. These machines are highly versatile and used across various sectors from medical to industrial products.

Considerations:

Slower speed compared to rotary presses

Perfect for scenarios where quality and customization matter more than quantity

In addition to the above types of tablet presses, there is also a Benchtop pill Press designed specifically for home users, small laboratories, and startups. It is affordable and easy to operate and can be used by users to experiment with tablet formulations.

To understand how a pill press works, let’s break down the basic mechanics behind the tablet compression process.

Filling: Powdered material — a blend of active ingredients and excipients — is fed into the die cavity via a hopper.

Metering: An upper and lower punch move into the die to control the exact amount of powder to be compressed.

Compression: The punches apply high pressure to compress the powder into a solid, uniform tablet.

Ejection: The lower punch pushes the finished tablet out of the die and into the collection area.

This entire cycle happens in seconds, especially in automated systems where multiple tablets are continuously produced.

While the core steps remain the same across all types of presses, different machines execute them in unique ways. For example, single-punch presses perform these steps one at a time, making them ideal for small-scale use, while rotary tablet presses carry out filling, compression, and ejection simultaneously across multiple stations, enabling high-speed, continuous production.

A pill press machine consists of several critical components that work together to ensure precise and consistent tablet production.

Dies: Molds that define the shape and size of the tablet.

Punches (Upper and Lower): Metal rods that compress the powder inside the die to form the tablet.

Hopper: Feeds the powdered material into the system; proper calibration ensures accurate dosing.

Turret (in Rotary Presses): Rotates the dies and punches for continuous, high-speed operation.

Compression System: May be hydraulic or mechanical, providing the force required to compact the powder.

Feeder: Ensures uniform powder delivery to the die cavity, crucial for quality control.

Ejection Mechanism: Removes the finished tablet from the die after compression.

In addition to hardware, the compression method also plays a key role in tablet formation. Common methods include direct compression, wet granulation, and dry granulation — each suited to different formulations and production needs.

Pill presses play a crucial role across multiple industries. Let’s explore some of the most common applications:

In the pharmaceutical industry, pill presses are indispensable. They ensure consistent dosing, tablet hardness, and appearance — all critical factors for regulatory approval and patient safety.

From antibiotics to antihypertensives, nearly every oral medication comes in tablet form thanks to advanced rotary presses.

The supplement industry heavily relies on pill presses to manufacture vitamins, minerals, probiotics, and herbal remedies. Consumers demand convenience and consistency, which pill presses deliver efficiently.

With the growing popularity of CBD and cannabis-based treatments, pill presses are increasingly used to produce standardized doses of cannabinoids in tablet form. This allows for precise dosing and easier consumption compared to oils or edibles.

Pharmaceutical and academic research labs use pill presses to develop new drugs and test formulations. These machines help scientists determine the optimal compression force, disintegration time, and dissolution rate of experimental compounds.

Some individuals use mini pill presses for personal health goals, such as making custom vitamin blends or herbal tablets. However, it's important to note that using a pill press at home for anything other than personal use may raise legal concerns.

When it comes to selecting a reliable and high-performance tablet press, LTPM stands out as your ideal partner. We offer a wide range of pill presses—from entry-level single-punch models to advanced rotary machines—designed to meet diverse production needs. All our machines are built with precision, ensuring consistent tablet quality, durability, and ease of operation. Whether you're a small lab or a large-scale manufacturer, LTPM delivers cost-effective, GMP-compliant solutions tailored to your requirements. With comprehensive after-sales support, easy maintenance, and expert technical guidance, we empower your success at every step.

Contact us today by [email protected] to find the perfect tablet press for your business!

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.