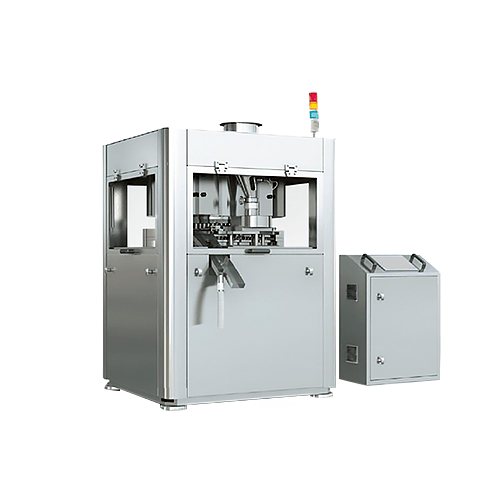

Choosing a tablet press isn’t just another equipment purchase. It’s a long-term strategic decision that will directly impact your product quality, production efficiency, and regulatory compliance for years to come.

Many buyers make the mistake of focusing solely on price tags or maximum speed claims. The real challenge lies in finding the machine that perfectly aligns with your specific formulations, production scale, and future growth plans.

This guide outlines the 12 essential factors you must evaluate to make an informed decision and secure a reliable return on investment.

Don't just look at the maximum speed on paper. What matters is the sustainable, quality-assured speed with your specific powder blend.

A machine rated for 300,000 tablets/hour might only achieve that with ideal materials. For challenging formulations, the effective speed could be 30-40% lower.

Pro Tip: Always request a trial run with your own material. Observe not just the output, but also tablet hardness uniformity and any defect rates at the target speed.

Your punches and dies define your tablet's shape, identity, and mechanical strength. Ensure the press supports your required standard to avoid costly custom tooling and supply chain delays.

B Tooling (TSM Standard): 19mm punch head, the global benchmark for most pharmaceutical tablets up to 13mm.

D Tooling: 25.4mm punch head, used for large tablets like effervescents, veterinary medications, or nutraceutical "megadoses."

EU Standards: Differ slightly in punch head angles and lengths. Crucially, B and EU tooling are NOT directly interchangeable on the same turret.

For facilities running multiple products, changeover time is pure waste. Modern presses address this with:

Tool-Less Turret Systems: The entire turret can be swapped in under 15 minutes using quick-release clamps instead of dozens of bolts.

Cartridge-Based Dies: Dies are pre-set in external cartridges, allowing an entire set to be inserted as one unit, eliminating individual die adjustment.

The feeder is the "heart" of the compression cycle. An inappropriate feeder is the leading cause of weight variation—the most critical quality defect.

Gravity Feeders: Rely solely on powder flowing into dies by weight. Only suitable for materials with excellent flowability (Carr Index < 20). Most real-world formulations, especially with active ingredients, do not meet this.

Force Feeders (Paddle Feeders): Use rotating paddles to actively push material into the die cavity. Essential for 80% of pharmaceutical powders with poor-to-moderate flow. Look for feeders with adjustable paddle speed and direction.

Dual/Quadruple Feeders: Used for bi-layer or triple-layer tablets, keeping powders separate until compression.

Choosing between manual, semi-automatic, and fully automatic tablet presses is not just about budget—it defines your daily operations, labor strategy, and scalability path.

| Aspect | Manual Pill Press | Semi-Automatic Single Punch Tablet Press | Fully Automatic (Rotary) Tablet Press |

|---|---|---|---|

| Operation Mode | Each tablet cycle is manually activated (lever/button). | Runs automatic compression cycles, but requires manual feeding, sampling, and collection. | Full-line automation: Auto-feeding, compression, in-process control, rejection, and discharge to downstream packaging. |

| Typical Output | Very Low: Up to 3,000 tab/hr | Low-Medium: 3,500 – 5,000 tab/hr | High-Very High: 13,000 – 600,000+ tab/hr |

| Ideal Application | • R&D & Formulation Labs • Clinical Trial Manufacturing • Pharmacy Compounding • Universities & Training | • Pilot Plants • Small-Scale Nutraceutical Production • CDMOs with diverse, small batches | • Medium/Large Commercial Pharma Production • High-Volume Nutraceuticals • Products with stable, validated formulas |

| Key Advantages | • Lowest capital cost • Maximum flexibility for recipe changes • Simple operation & maintenance | • Good balance of cost and output • Easier to clean & changeover than full auto • Less labor-intensive than manual | • Highest output & consistency • Lowest cost per tablet at scale • Minimal operator intervention • Ready for MES/ERP integration |

| Key Limitations | • Labor-intensive • Quality depends on operator skill • Not scalable for commercial batches | • Requires constant operator attendance • Higher risk of human error in sampling/feeding • Output ceiling limits growth | • Highest upfront investment • Requires skilled maintenance staff • Less economical for very small batches |

| Automation & Control | Basic start/stop; manual parameter adjustment. | PLC with cycle control; may have basic data logging. | Advanced HMI with recipe management, SPC, 21 CFR Part 11 compliance, remote access. |

| Total Cost of Ownership (TCO) Profile | Low Capex, High Opex (labor). Cost-effective only for minuscule volumes. | Moderate Capex, Moderate Opex. Best for low/medium volumes with variable products. | High Capex, Low Opex. Delivers the lowest cost per tablet over 5+ years at scale. |

Pro Tip: Don’t view automation as a binary choice. Many modern “fully automatic” presses offer manual override modes for setup and troubleshooting, and some semi-automatic models can be retrofitted with automatic feeders.

Learn more information about types of Tablet Press Machines

In pharmaceutical production, cleaning validation is a regulatory requirement. The machine design must make effective cleaning easy, fast, and verifiable. Poor design can turn a 30-minute wash-down into a 4-hour ordeal.

Material: All product contact parts must be 316L or higher-grade stainless steel, polished to a mirror finish (Ra < 0.8 µm). A rough surface harbors residue and biofilms.

Construction: Seek tool-free disassembly. Clamps and quick-release levers should allow an operator to remove the feeder, hopper, and compression zone covers without tools.

Geometry: No dead legs, pockets, or inaccessible corners. Surfaces should be sloped to allow complete drainage. The frame should be fully enclosed, preventing lubricants from the drive mechanism from contaminating the product zone.

Modern tablet presses are data centers. Your control system should:

Offer recipe management for different products

Provide real-time monitoring of pressure, weight, and production counts

Include automatic rejection of out-of-spec tablets

Be 21 CFR Part 11 compliant with full audit trails

Allow remote access for technical support

Avoid machines with basic PLCs that can't store batch data or connect to your MES system.

Operator safety is paramount, and regulations are tightening, especially for potent compounds.

Noise: Sustained exposure above 80 dB(A) requires hearing protection. Well-designed presses operate below 75 dB(A).

Dust: Integrated HEPA-filtered dust extraction at compression and take-off points is standard for GMP. It protects operators and prevents cross-contamination.

Containment for HPAPIs: For handling Highly Potent Active Pharmaceutical Ingredients (HPAPIs), evaluate the offered Occupational Exposure Band (OEB) containment level.

Machine Safety: Emergency stop buttons at multiple points, mechanical guards on all moving parts, and interlock systems that prevent operation when guards are open.

The safest system is one that is used correctly. Overly cumbersome containment can lead to procedural shortcuts. Look for designs where safety features are integrated without making routine sampling and cleaning prohibitively difficult.

Ease of maintenance directly impacts uptime. A machine that requires a week to replace a simple part is not reliable, no matter how well it's built.

Modularity: Key sub-assemblies (feeder drive, compression roller units) should be removable as a module for bench repair while the machine is otherwise operational.

Standardization: Use of standard bearings, seals, and motors available from multiple industrial suppliers, reducing spare part lead times.

Accessibility: Clear, numbered service ports and large access panels. Good lighting inside the machine frame. 3D interactive electronic service manuals are a sign of a forward-thinking supplier.

Local Support: Does the supplier have a local technical center with common spare parts in stock? What is the guaranteed on-site response time for a critical failure?

You are entering a 10+ year partnership. The supplier's knowledge and support infrastructure are as critical as the steel in their machine.

Process Engineering Support: Do they have application engineers who can discuss your formulation challenges (e.g., moisture sensitivity, sticking) and suggest machine settings or tooling coatings? Or do they only quote from a catalog?

Pre-Sale Testing: The most valuable service. Will they run a substantial batch of your powder and provide a detailed report on compaction behavior, optimal speed, and potential issues?

After-Sales Structure: Is support a centralized call center or regionally based engineers? What are the business hours for technical phone support? Is remote diagnostics software included?

Your needs will evolve. The machine you buy today should not be obsolete in five years.

Features That Enable Future Growth:

Industry 4.0 Ready: Has built-in OPC UA or Ethernet/IP communication for seamless, plug-and-play data exchange with your MES or plant-wide SCADA system.

Sensor & Camera Ready: Provides power and data ports to easily add in-line near-infrared (NIR) probes for blend uniformity, or high-speed vision systems for defect detection.

Software Upgradability: The operating system should allow for feature additions via software license, not hardware replacement.

Modular Physical Design: A frame that allows for the future addition of external modules, like a dedicated dedusting unit or automatic punch inspection station.

A complete, well-prepared documentation package is not a "nice-to-have"; it is the cornerstone of your regulatory compliance and can save months of internal work.

Qualification Protocols: Ready-to-execute Installation (IQ), Operational (OQ), and Performance (PQ) protocols, tailored to your machine's serial number.

Certificates: Material certificates (CofC) for all GMP-contact materials, calibration certificates for all pressure transducers and sensors.

Technical Documentation: Full 3D CAD models (for factory layout planning), P&ID diagrams, and detailed electrical schematics.

Risk Documentation: A preliminary Failure Mode and Effects Analysis (pFMEA) or other risk assessment for the equipment.

The purchase price is the tip of the iceberg. A comprehensive TCO analysis prevents "sticker shock" from ongoing costs and reveals the true economic winner.

| Cost Component | Typical Range | What to Check |

|---|---|---|

| Initial Purchase | 40-60% of TCO | Includes machine, installation, validation |

| Energy Consumption | 8-12% of TCO | Servo motors vs traditional motors |

| Maintenance & Parts | 15-20% of TCO | Availability and cost of spare parts |

| Downtime Losses | 10-25% of TCO | Machine reliability and service response |

| Tooling Replacement | 5-10% of TCO | Punch and die lifespan |

Selecting the right tablet press requires transforming a complex array of technical specs into a confident, strategic decision. By methodically evaluating these 11 factors—from the granular technical fit to the broader partnership—you move beyond price tags to understand total value and long-term risk.

At LTPM, we believe the proof is in the performance. We invite you to go beyond specifications and see real results. Contact our technical team today to start a data-driven conversation about your tablet production future.

We use cookies to enhance your browsing experience and protect your privacy. Please read our privacy policy for more information.