Low Shear Pump

The Low Shear Pump Flat Vane Pump by Wenzhou Boao Mechanical Manufacturing Co., Ltd. is a revolutionary advancement in low-shear pumping technology. Engineered with a unique flat-plate impeller, it fundamentally redefines gentle fluid handling. Unlike conventional centrifugal pumps that rely on high-speed impact, our pump utilizes the fluid's own viscosity to create a smooth, laminar (sheet) flow. This method ensures the most sensitive products—from fragile blood cells and dairy emulsions to fruit juices and long-fiber slurries—are transported with virtually zero damage or product degradation. Designed for ultimate reliability and minimal maintenance, it is the optimal solution for demanding, corrosive, and abrasive applications where product integrity and pump durability are paramount.

- Product Description

- Specification Parameter

- Product Application

- Product Feature

- More Details

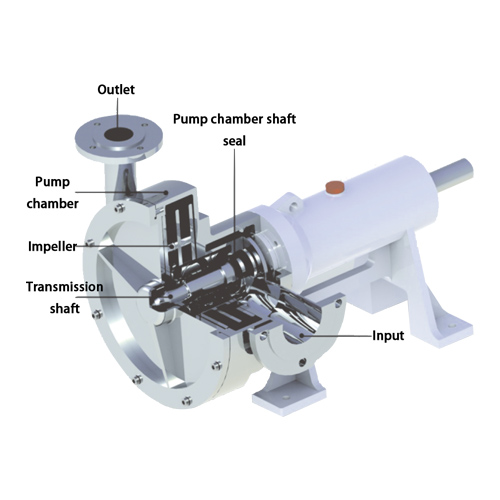

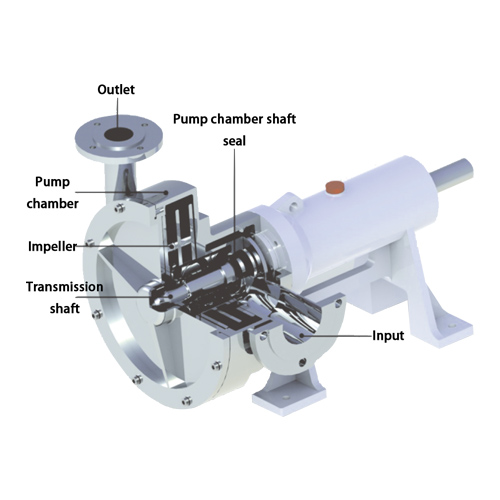

Product Description

The Flat Vane Pump by Wenzhou Boao Mechanical Manufacturing Co., Ltd. is a revolutionary advancement in low-shear pumping technology. Engineered with a unique flat-plate impeller, it fundamentally redefines gentle fluid handling. Unlike conventional centrifugal pumps that rely on high-speed impact, our pump utilizes the fluid's own viscosity to create a smooth, laminar (sheet) flow. This method ensures the most sensitive products—from fragile blood cells and dairy emulsions to fruit juices and long-fiber slurries—are transported with virtually zero damage or product degradation. Designed for ultimate reliability and minimal maintenance, it is the optimal solution for demanding, corrosive, and abrasive applications where product integrity and pump durability are paramount.

Specification Parameter

Model | Flow Rate (t/h) | Head (m) | Power (KW) | Speed (r/min) | Inlet | Outlet |

BOBP20-20-120 | 2 | 8 | 0.55 | 2840 | DN20 | DN20 |

BOBP32-25-150 | 5 | 20 | 1.1 | 2840 | DN32 | DN25 |

BOBP50-40-200 | 10 | 35 | 4 | 2840 | DN50 | DN40 |

BOBP65-50-200 | 25 | 35 | 5.5 | 2840 | DN65 | DN50 |

BOBP80-65-200 | 50 | 35 | 11 | 2800 | DN80 | DN65 |

BOBP100-80-250S | 70 | 20 | 7.5 | 1450 | DN100 | DN80 |

BOBP150-100-300S | 100 | 32 | 15 | 1450 | DN150 | DN100 |

BOBP200-150-300S | 200 | 30 | 30 | 1450 | DN200 | DN150 |

BOBP250-200-400S | 400 | 48 | 75 | 1450 | DN250 | DN200 |

Product Application

This versatile pump is indispensable across industries that require gentle, reliable, and efficient transfer of challenging fluids:

Food & Beverage: Perfect for juices, milk products, yogurt, wine, tomato paste, and starch where maintaining texture, viscosity,

and cell structure is critical.

Health production & Biotech: Ideal for transporting cell cultures, blood products, protein solutions, and other shear-sensitive

biological fluids without cellular damage.

Pulp & Paper: Excellently handles paper pulp, long-fiber slurries, and coatings without fiber shortening, dehydration, or

clogging.

Chemical & Wastewater: Robustly manages abrasive slurries, corrosive chemicals, polymers, and sewage containing solids and

entrained gases.

General Industry: A reliable choice for pumping suspensions, adhesives, paints, and any medium where shear degradation, abrasion,

or gas handling is a concern.

Product Feature

-

1

1. Zero-Product Damage: Ensures nearly 100% product preservation. Proven to transport fragile substances like blood plasma and delicate fruit cells without destruction, whereas other pumps may cause up to 20-40% product loss.

-

2

2. Exceptional Abrasion & Corrosion Resistance: Features an extremely durable construction. Tests show no internal damage after continuous operation with 10-80mm rocks in the chamber, making it ideal for harsh, corrosive, and slurry-handling environments.

-

3

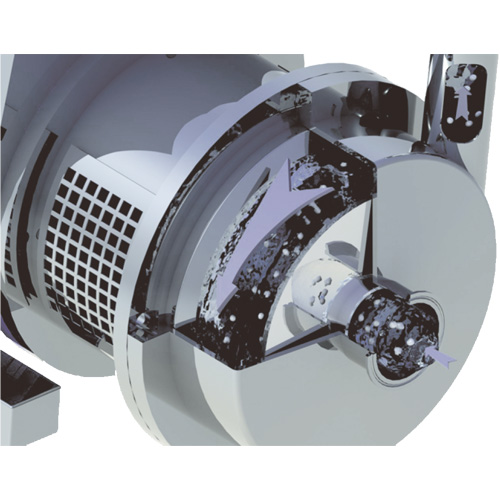

3. Handles High Gas Content & Solids with Ease: Uniquely manages fluids containing over 70% entrained gas without cavitation, noise, or vibration. Its non-clogging design effortlessly passes solid particles, long fibers (like kelp and paper pulp), and sediments without blockage or fiber loss.

-

4

4. Low Maintenance & High Reliability: Operates with no impact, minimal pulsation, and negligible radial load. This results in exceptionally low wear on the impeller and casing, drastically reducing the need for part replacements and downtime.

-

5

5. Maintains Product Consistency: Prevents dehydration or separation in fibrous and non-Newtonian fluids (e.g., starch, pulp), ensuring uniform output quality.

More Details

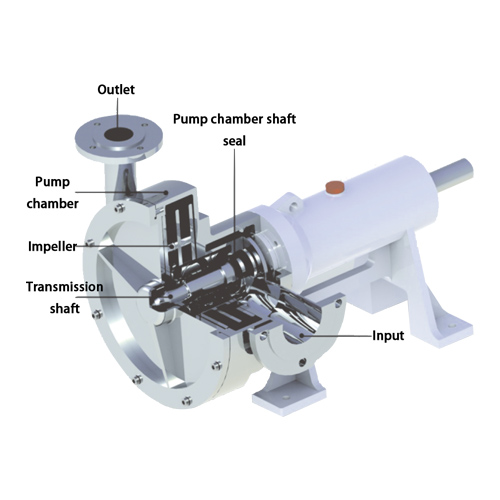

Axial Flat Vane Pump

The ZTSP pump distinguishes itself from conventional centrifugal and sanitary pumps through two core design innovations, each delivering multiple operational and economic benefits.

More Details

Axial Flat Vane Pump

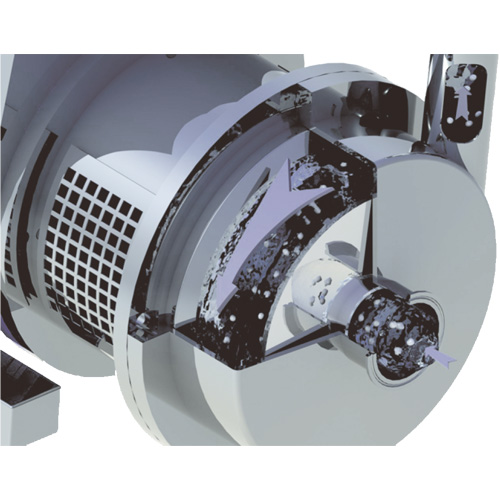

ZTSP Pump: The inlet is at the rear, in line with the drive shaft.Advantage:

1. Creates a permanent negative pressure zone at the shaft seal during operation, preventing product leakage and significantly lowering sealing requirements.

2. Eliminates axial shaft movement caused by varying discharge pressures, drastically reducing impeller and casing wear for longer service life.

More Details

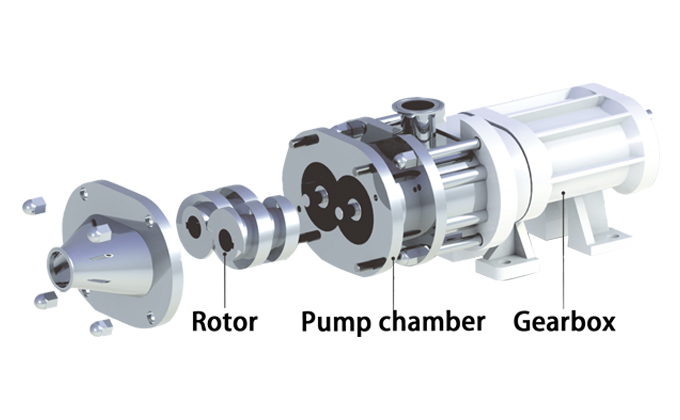

Screw Pump

The SLGP Series Sanitary Twin Screw Pump is a high-performance, modular positive displacement pump designed for maximum efficiency and versatility in handling the most demanding fluids. Operating on a gentle, low-pulsation principle, it is exceptionally suited for shear-sensitive, viscous, non-lubricating, or solids-laden media. Its unique contact-free, intermeshing screw design ensures no metal-to-metal contact, allowing it to convey abrasive and corrosive materials with minimal wear. Offering an impressive operational range—from 40 L/h to 150 m³/h flow, handling viscosities from 1 to 500,000 cSt, and particles up to 40mm—this pump is a comprehensive solution. Furthermore, its ability to run at speeds up to 3600 rpm enables it to function as both a product transfer pump and a Cleaning-in-Place (CIP) unit, consolidating processes and reducing system complexity. It is engineered to meet stringent GMP, 3A, and FDA hygiene standards.

More Details

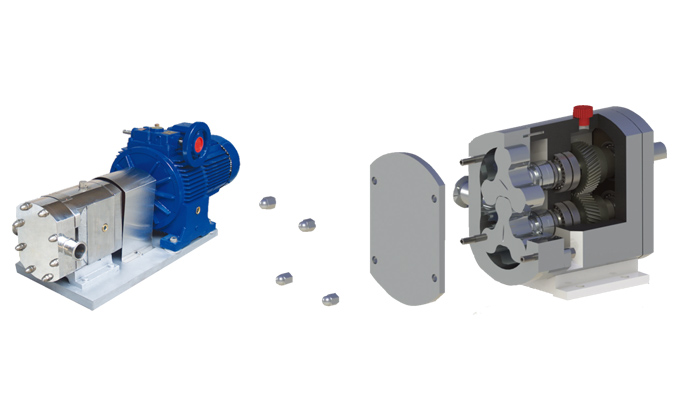

Rotary Lobe Pump

1. Optimized Compact Design: The TRA series features an integral coupling assembly that reduces the pump's overall length by 100-250mm. This space-saving design not only makes the unit more compact and aesthetically pleasing with its mirror-polished stainless steel casing but also eliminates the risk of paint chipping and contamination.2. High Efficiency & Durability: This innovative integrated drive system minimizes power loss, noise, and wear typically associated with standard elastic shaft couplers. The result is higher operational efficiency, the lowest internal slip, and a significantly extended service life.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China