-

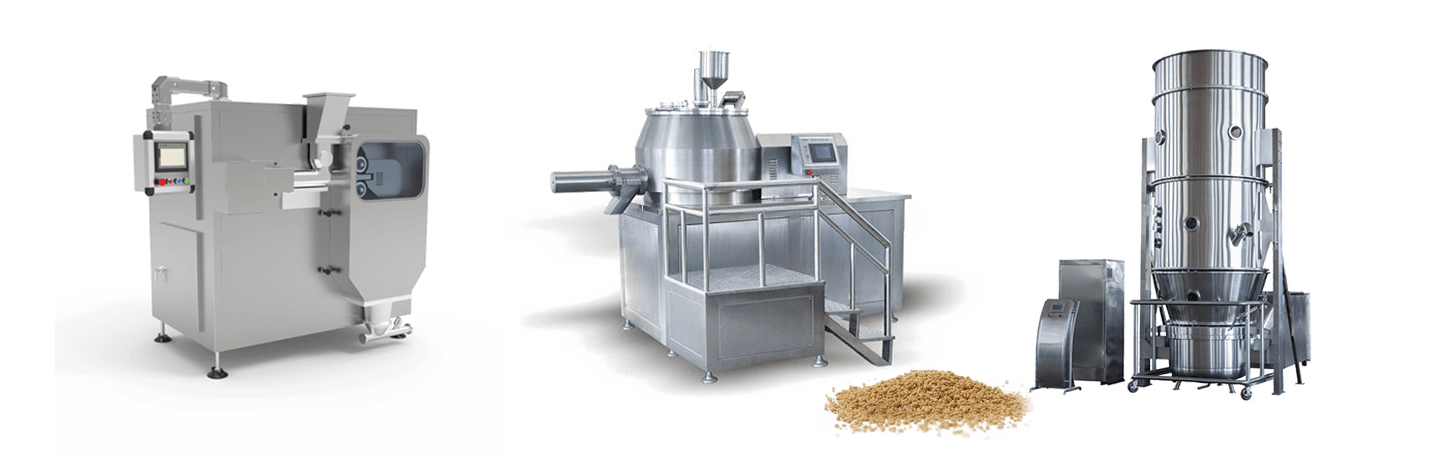

GHL Series High Speed Wet Mixer and Granulator

Inquire

-

FL Series Boiling Spray Granulation Drying Machine One-step Granulator

Inquire

-

GZL Series Dry Granulator

Inquire

Advantages of Our Powder Granulator Machines

Precision Particle Engineering: Achieve a consistent particle size distribution to ensure uniform tablet weight and stable active ingredient release.

Dust-Free & Aseptic Design: All our pharmaceutical granulator machines feature airtight construction to prevent powder leakage, protecting both the operator and the product from cross-contamination.

Durable & Compliant Materials: Constructed with mirror-polished SS316L or SS304, our equipment is built to withstand rigorous cleaning protocols and meet FDA requirements.

Smart Control Systems: Integrated PLC and HMI touchscreens allow for precise monitoring of pressure, speed, and granulation time for repeatable results.

FAQ

-

What are the advantages and disadvantages of dry granulation and wet granulation?

Dry granulation allows powder to be directly turned into granules without the addition of any binders or additives, making it easier to control the production process and material composition. However, it is generally more limited in terms of the types of materials that can be processed. Wet granulation, on the other hand, involves the addition of a liquid binder to improve the uniformity of granules, making it suitable for a wider range of materials. The downside is that it requires more equipment and steps, and the drying process can be time-consuming.

-

Does the dry granulation machine require a binder?

No, the dry granulation machine does not require a binder. It works by directly compressing the powder into granules without the need for additional binders or additives.

-

How long does one batch of wet granulation typically take?

One batch of wet granulation typically takes 10-15 minutes.

-

Can the particle size in a dry granulation machine be adjusted by changing the screen?

Yes, different mesh screens can be used for granulation according to the customer's requirements to achieve the desired particle size.

-

Which industry is the LTPM powder granulator machine designed for?

LTPM's machines are specifically built for the pharmaceutical, nutraceutical, and food industries. Unlike standard industrial granulators, a pharmaceutical granulator machine must meet strict sanitary standards. We use FDA-approved materials and specialized designs to ensure that every batch of powder is processed under aseptic conditions.

-

Can your granulators handle powders with different flow characteristics?

Yes. LTPM's systems are highly adjustable. By fine-tuning the roller pressure, feeding screw speed, and selecting the appropriate mesh screen, you can optimize the machine for various powder types—from cohesive extracts to free-flowing chemical bases—achieving the exact granule density you require.

-

How do you ensure the yield rate during the granulation process?

LTPM's equipment is engineered with a high-precision feeding and recovery system, allowing for a material conversion rate of up to 99%. This minimizes waste of expensive active ingredients and ensures high efficiency in both lab-scale and large-scale manufacturing.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China