Automatic & Semi-automatic Capsule Fillers

LTPM's capsule fillers combine versatility with high-performance production, supporting a complete range of capsule sizes and types through both fully automated and semi-automated models. Designed to scale seamlessly from pilot batches to full commercial output, our machines deliver industry-leading speeds of up to 220,000 capsules/hour while maintaining exceptional ±3% weight accuracy across all production volumes. Download our product Catalog here.

Product video

Powder & Granule Production

Captop capsule filling

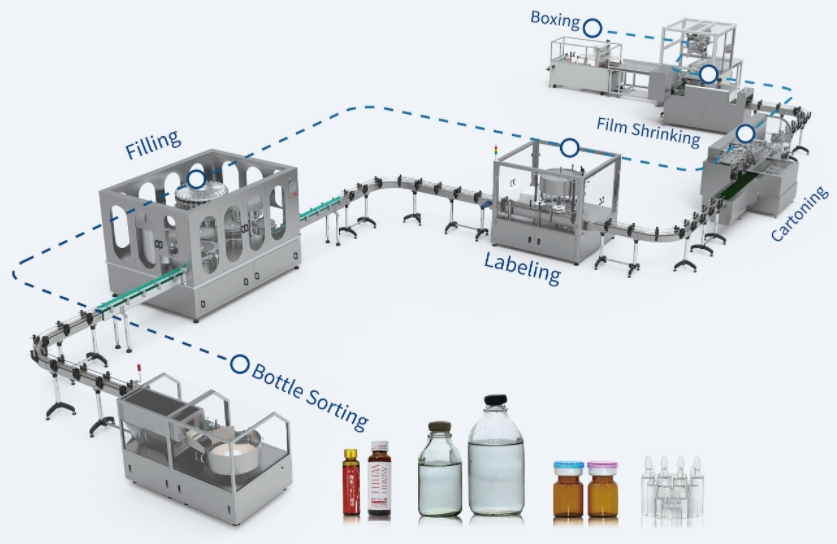

Liquid Dosage Solutions

LTPM offers a range of machines and solutions from raw material sterilization, liquid preparation, automatic aseptic filling, sealing to finished product inspection, no matter what form or application of liquid dosage you want to produce.

Learn More

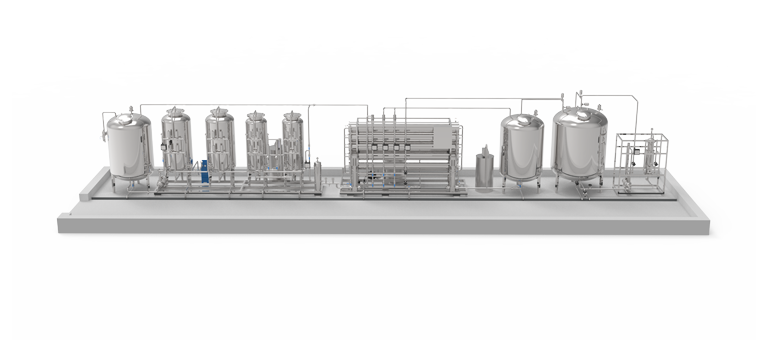

Pharma Water Solutions

LTPM is able to provide pharmaceutical water solutions. According to the customer's raw water conditions and water needs, LTPM uses a variety of technologies such as distillation, ion exchange, electrodialysis, reverse osmosis, ultrafiltration membranes, etc. to produce purified water or water for injection (WFI).

Learn More

Latest news

Learn MoreFAQ

-

What is a capsule filling machine called?

A capsule filling machine, also called a capsule filler or encapsulator, is an automated pharmaceutical device that precisely fills empty capsule shells with powders, pellets, liquids or tablets. These machines are essential for efficient, high-volume production of medicines and supplements in gelatin or HPMC capsules.

-

Can the ProCap-2 double-head semi-automatic capsule filling machine be made of 316L?

The capsule plate can only be made of aluminum. If the others are replaced with stainless steel 316L, the price will be increased by 800USD extra.

-

JTJ-A semi-automatic capsule filling machine, can the language of the touch screen be French? Do I need to add money?

The language of the touch screen can be changed to French without any additional money. If the touch screen is added, an additional 800USD is required.

-

What types of capsules can be filled using our LTFK Series capsule filling machine?

The LTFK Series full automatic capsule filling machine supports gelatin, HPMC, pullulan, and enteric-coated capsules in all standard sizes (#5 to #000), handling powders, pellets, tablets, and liquids for pharmaceutical and nutraceutical production.

-

What is the difference between semi-automatic capsule filling machine JTJ-A and DTJ-V?

1. All the molds of JTJ-A are stainless steel except for the capsule plate. DTJ-V are all copper.

2. The operating platform of JTJ-A is formed at one time, which is more convenient to clean.

3. JTJ-A speed control has three sowing capsules, powder adding screw and powder adding turntable. DTJ-V has only two powder adding screws and powder adding turntable. -

The vacuum pump of the double-head semi-automatic capsule filling machine leaks oil and heats up. Why?

There are three reasons: The cloth bag is blocked, the voltage is unstable, and the seal is not good.

-

How much does a capsule filling machine cost?

Semi-automatic capsule fillers start at $9500 - $13000, while fully automatic models range from $15000 - $150000. Final pricing depends on capacity, automation level, and added functionalities like PAT monitoring or containment systems.

-

What quality inspection systems are available for the LTFK capsule filling machines?

Our LTFK capsule filling machines incorporate a comprehensive suite of advanced inspection technologies designed to ensure pharmaceutical-grade quality control throughout the production process.

The integrated system features real-time process monitoring through our Net Weight Detection System (NWDS), which utilizes electromagnetic field sensors to maintain ±1-3% dosing accuracy with automatic self-calibration.

For enhanced process reliability, the PAT Classic system continuously monitors powder height, ejection force, and capsule closing pressure to prevent defects and machine damage.

We've also implemented intelligent automation including the ASB self-correction function that reduces downtime by automatically resolving capsule handling errors, along with our "No Cap - No Fill" technology that prevents product loss by pausing dosing when capsule shells are missing.

Together, these technologies deliver closed-loop quality assurance that meets strict GMP requirements while maximizing production yield.

-

Does the capsule filling machine need a water chiller?

If it is a water ring vacuum pump, water is required for sealing to generate vacuum condition. But we will distribute the water tank to protect the vacuum pump from damage caused by overheating. Of course, if you are going to use dry vacuum pump, it won’t need any water or oil for Automatic capsule filling machine.

-

What kinds of material transfers are available for the automatic capsule filling machine?

The automatic capsule filling machine has an empty capsule feeder and a powder feeder.

-

What kinds of formulations can your capsule fillers encapsulate?

Our capsule filling machine handles all standard and advanced capsule filling requirements with precision. The machines dose powders (free-flowing to cohesive), granules, and pellets through an optimized slide-gate system. For pellets, a dedicated gentle dosing station preserves coating integrity across various sizes.

Tablet encapsulation covers micro-tablets (from 0.8mm) to standard oblong tablets (up to 8mm), including multi-tablet combinations. The vacuum-wheel micro-dosing system achieves high accuracy (±3%) for APIs and DPI formulations. Liquid dosing handles hydrophilic to thixotropic fluids with temperature control.

2025.07.31

2025.07.31

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China