-

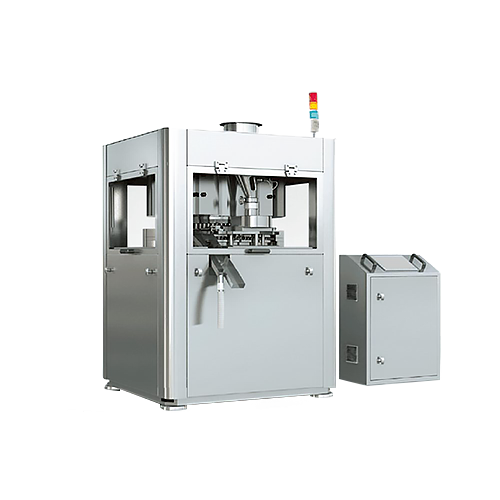

ZPS226-8PLC Bi-layer Rotary Tablet Press Machine

Inquire

-

GZP Series High Speed Rotary Tablet Press Machine

Inquire

-

EffeTop-27D Effervescent Tablet Pressing Machine

Inquire

-

ZPT420-31D Rotary Milk Tablet Press Machine

Inquire

-

ZTP-60 Single Punch Tablet Press Machine

Inquire

-

LTDP Series Desktop Tablet Press Machine

Inquire

-

ZP Series Rotary Tablet Pressing Machine

Inquire

Tablet press machines are essential for compressing powder into solid tablets. Equipped with high-precision systems, they produce consistent results even for complex formulations. These machines are user-friendly, durable, and highly customizable.

Product video

GZPK series tablet press machine

High-speed Tablet Press Machine

Latest news

Learn MoreFAQ

-

What is a Tablet Press Machine

A tablet press machine is a device that compresses powder into tablets of uniform size and shape. It is widely used in pharmaceutical, chemical, and food industries for efficient, large-scale production of tablets. Learn more about what is a pill press.

-

How does a tableting machine work?

A tableting machine operates by feeding granulated material into a die cavity via a hopper. As the turret rotates, upper and lower punches move to compress the material under controlled pressure, forming tablets of precise weight, thickness, and hardness. This process ensures uniform quality, critical for pharmaceutical manufacturing, and supports high-volume production with consistent output.

-

Which Machine Is Used in the Formulation of Tablets?

Both single punch tablet press machines and rotary tablet presses are used in the formulation of tablets, depending on the stage and scale of production.

Single Punch Tablet Press Machines are commonly used during the early development and testing stages. These machines require only small amounts of powder to produce test tablets, allowing researchers to evaluate the compressibility, hardness, and overall quality of the formulation. The single punch tablet press applies controlled pressure to compress granules or powders within a die cavity, producing tablets with consistent weight, thickness, and hardness — all critical factors for pharmaceutical quality and process efficiency.

For large-scale production, Rotary Tablet Presses are preferred due to their higher efficiency and ability to handle multiple dies simultaneously. This ensures uniformity across thousands of tablets per minute, making them ideal for industrial-scale manufacturing where consistency and high output are crucial.

Other machines also play important roles in the full tablet formulation process:

Mixer/Blender: Ensures uniform blending of active ingredients and excipients. Learn more about our powder mixing machine.

Granulator: Converts powder into granules for better flow and compression.

Coater (optional): Applies a coating to modify drug release or improve appearance.

-

What Are the Differences Between ZP, ZPT, GZP, and FZP Series Tablet Press Machines?

Choosing the right tablet press machine depends on your specific production needs. Here’s a quick overview of each series:

ZP-Series is our standard tablet press machine which can do Max. 25mm diameter.

ZPT-Series is our improved type tablet press machine which comes with automatic lubrication system and all features the same to high speed tablet press machine, just with slower rotation speed than high speed tablet press machine.

GZP-Series is our high speed tablet press machine which can do Max. 110rpm/min with Max. 25mm diameter.

FZP-Series is our non-standard tablet press machine which can be customized according to client requirement, especially when you have bigger tablet size which exceed our 25mm diameter.

Download our product Catalog to learn more Specification Parameter. -

How much does a pill press machine cost?

The cost of a pill press machine varies depending on the type and specifications.

Single Punch Tablet Press Machines typically range from $1800 to $3000, making them an affordable choice for small-scale production, laboratories, or R&D purposes.

Rotary Tablet Press Machines are more advanced and designed for high-volume production. Their prices generally range from $6000 to $120000, depending on speed, pressure capacity, and level of automation.

Investing in the right machine depends on your production needs, budget, and compliance requirements. -

The difference between the European standard B punch and the European standard D punch in the tablet pressing machine.

European standard: IPT

D-type punch refers to the diameter of the punch rod: 25.35mm, the middle mold: 38.1mm,

B-type punch refers to the punch diameter: 19mm, the middle mold: 30.16mm,

BB type punch refers to the punch diameter: 19mm, the middle mold: 24mm,

Therefore, after confirming the die type, the tablet diameter is determined.

In other words, after confirming the maximum sheet diameter, the type of die can be confirmed. -

How Does LTPM Cater to Different Pill Manufacturing Requirements?

As a professional tablet press machine manufacturer, LTPM caters to diverse tablet manufacturing needs with a wide range of presses. From single punch machines for small-scale and R&D purposes to rotary presses for high-volume output, and high-speed models for optimal efficiency. We also provide economical benchtop presses and advanced systems ensuring precise control over tablet attributes. Choose LTPM for tailored solutions that meet your specific demands.

-

What is the maximum tablet size of the tablet press machine?

Determined according to the specific model. The standard European standard type D is 25 mm in diameter. If there are special requirements, we need to customize for you.

-

How Does Tablet Press Technology Handle Varying Powder Properties?

Tablet press technology handles varying powder properties through precision filling systems, variable compression force, and automated real-time monitoring. These features ensure uniform fill weights and optimal hardness for each pill, regardless of powder density or flowability. By adjusting compression force and using material conditioning techniques, tablet presses can manage a wide range of powders, producing pills with consistent weight, hardness, and dissolution profiles.

-

What are the advantages of hydraulic tablet pressing machine in terms of performance and stability?

The hydraulic tablet press is relatively easy to adjust the pressure, but there is a risk of oil leakage. Now our GZP-Series and ZPT-Series can equip with automatic pressure adjustment system without hydraulic system.

-

What is a pre-compression system and what is the difference between a dual-compression single-out system?

Pre-compression is mainly used to remove powder and air to prevent uneven tablet weight. After the powder is pre-pressed, it reaches the main pressure. After the main pressure, the tablet reaches the target tablet weight and hardness. The size of the main pressure can be controlled through the touch screen. The main difference between pre-compression and double-pressure single-out is that there is only one feeding port for pre-compression, and two for double-pressure single-out.

-

Can your tablet presses produce different shapes and sizes of tablets?

Yes, our tablet presses are designed with interchangeable punches and dies, allowing the production of tablets in various shapes, including round, oval, rectangular, and custom designs. Key parameters such as fill depth and compression force are adjustable, enabling the machine to accommodate different tablet sizes and formulations. However, each machine has a maximum fill depth limit, which should be considered during equipment selection based on the required tablet thickness and weight. As a result, tablet presses offer great flexibility in producing tablets of various shapes and sizes, with customization options available to meet specific customer requirements.

2025.05.23

2025.05.23

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China