-

LabCoa-series Lab Scale R&D Coating Machine

Inquire

-

BG-B series Non-Pefopated Drum Film Coating Machine

Inquire

-

BG-series High-efficiency Coating Machines

Inquire

-

SHL Series Small Film coating machine

Inquire

-

BG-E series Drum Changeable Film Coating Machine

Inquire

Technical Data of LTPM Tablet Coating Machines

| Technical Parameter | Specification Range | Details |

|---|---|---|

| Batch Capacity | 5kg - 600kg | • Lab-scale: 1-40kg (LabCoa series) • Production-scale: 75-600kg (BG series) |

| Drum Types | Perforated / Non-perforated / Interchangeable | • BG-E: Quick-change drums • BG-B: Solid drum for large particles (>0.6mm) |

| Rotation Speed | 2-46 rpm | Adjustable per model (e.g., SHL: 0-46rpm) |

| Heating System | Ambient to 80°C | ±2°C temperature control accuracy |

| Air Filtration | 0.5μm HEPA (100,000 grade) | GMP-compliant airflow system |

| Coating Processes | Film/Sugar/Enteric/Controlled-release | Supports all major coating types |

Download our complete Tablet Coating Machine Technical Data (PDF) for detailed specifications

Product video

Tablet Coating Machine

Core Advantage

Smart Process Control

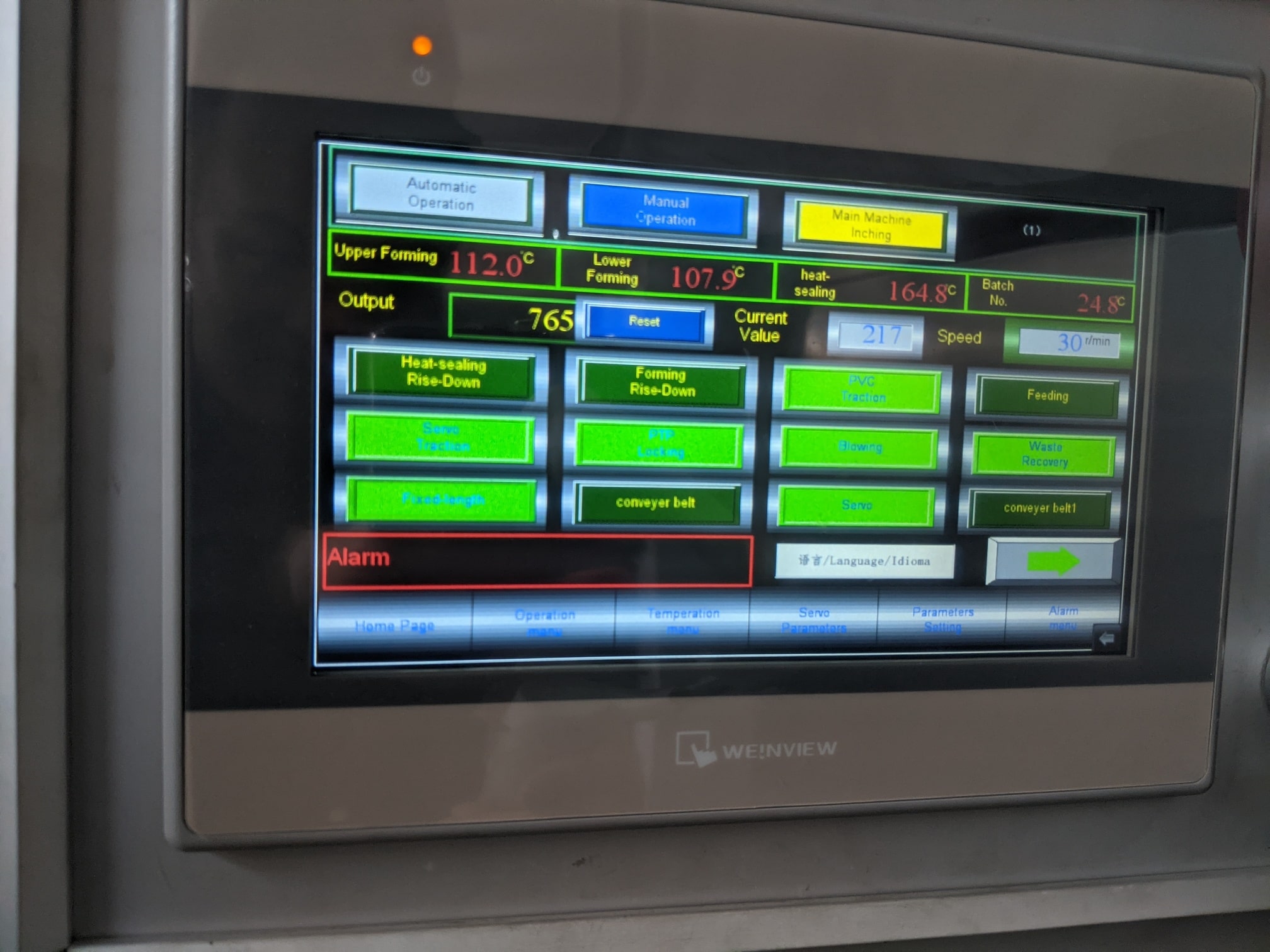

Our advanced control systems feature user-friendly HMI interfaces with programmable recipe storage, allowing operators to save and recall optimal coating parameters for different products. The system automatically records critical process data for full batch traceability, supporting GMP compliance and quality assurance requirements.

Efficient Cleaning Design

Designed for pharmaceutical-grade cleaning validation, our coating machines feature smooth product contact surfaces and strategically placed access points. The optimized cleaning system reduces water and solvent consumption while ensuring complete removal of coating residues between batches.

Precision Spray Technology

The adjustable spray arm system incorporates anti-clogging nozzles and optimized airflow patterns to achieve uniform coating distribution. Operators can fine-tune spray patterns and droplet size to accommodate various coating formulations, from aqueous films to organic solvent-based coatings.

Flexible Batch Processing

Our unique drum geometry and baffle design maintain consistent tablet movement across batch sizes from 5kg to 600kg. This ensures homogeneous mixing and coating uniformity regardless of production scale, with minimal adjustment between different product runs.

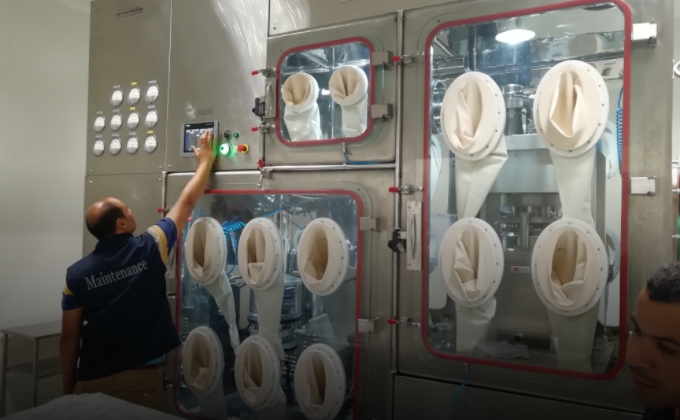

Contained Operation

For potent compound handling, we offer optional containment solutions including closed charging/discharging systems and integrated dust extraction. These features maintain operator safety while meeting containment requirements for OEB4/OEB5 compounds.

Process Monitoring

Integrated sensors continuously monitor bed temperature, airflow and coating progress. Real-time data feedback allows for immediate parameter adjustments to maintain optimal coating conditions throughout the batch process.

Latest news

Learn MoreFAQ

-

What is a tablet coating machine?

A tablet coating machine is specialized pharmaceutical equipment that applies a uniform outer layer (film, sugar, or functional coating) to tablets through a controlled process of spraying, drying, and polishing. It ensures precise drug delivery (e.g., delayed/sustained release), protects active ingredients, improves swallowability, and enables product identification. Modern systems feature GMP-compliant designs with automated controls for batch consistency.

-

What are the advantages of tablet coating?

Tablet coating serves multifunctional purposes: (1) Physical protection & identification (color/taste-masking); (2) Functional control via enteric/sustained-release coatings for targeted API delivery; (3) Active coating allowing API incorporation in the film layer. These ensure drug stability, patient compliance, and optimized therapeutic efficacy.

-

What are the principles of tablet coating?

Drum coating machines achieve functional tablet films through three core principles: (1) Uniform mixing for adhesion, (2) Controlled spray-drying kinetics, and (3) Real-time quality monitoring.

-

The main difference between a simple coating machine (BYC-Series) and a high-efficiency coating machine (BG-Series)

1. The high-efficiency coating machine is carried out in a closed system with negative pressure, and there will be no dust flying.

2. The high-efficiency coating machine is equipped with an air inlet fan and a suction fan. The suction will suck the coating powder onto the surface of the tablet, ensuring the coating effect and will not cause waste of materials.

3. The high-efficiency coating machine has a formula storage function to ensure that different batches can quickly read the formula without resetting.

4. The high-efficiency coating machine is equipped with an automatic air valve control system to automatically control the temperature and air volume.

5. The high-efficiency coating machine has a By pass function, which can realize the non-stop function of feeding and discharging, ensuring the consistency of production parameters of each batch, and does not need to reheat, which can be more energy-saving. -

How long is the process of one batch on Tablet Film Coating?

The working time of the coating machine is also different according to the actual output and medicinal formula, basically 2-4 hours per batch.

-

Is a changeable drum coating machine necessarily better than a non-changeable drum coating machine? why?

Changing the barrel can realize coating with different feeding amounts. When the amount of material is small, the coating pan will become smaller and the coating effect will be better.

-

Can the simple coating machine (BYC-Series) use hot air and cold air?

Yes.

-

What is the approximate temperature in the coating pan?

40-60 degrees Celsius, this needs to be based on actual needs.

2025.11.17

2025.11.17

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China